Table of Contents

When business leaders think “software,” they often picture cloud applications or mobile apps. But for companies building physical products, the most critical code is invisible. Embedded software development services create the foundational logic that lives inside a device, directly controlling hardware and enabling its core function.

This isn’t about user interfaces or databases. It’s about the deterministic, real-time code that actuates a robotic arm, interprets data from a medical sensor, or manages the battery system in an electric vehicle. This software is the difference between a product that works flawlessly and one that fails in the field, triggering costly recalls and irreparable brand damage.

The Strategic Role of Embedded Software in Product Success

In modern hardware, embedded software is the central nervous system dictating performance, reliability, and market viability. For leaders in aerospace, medical devices, and industrial automation, the primary challenge isn’t just perfecting mechanics or electronics; it’s the high-stakes integration of hardware and software under extreme resource and timeline constraints. This is where most ambitious product initiatives fail.

Diagnosing Common Failure Points

Problem: A product development initiative consistently misses deadlines and exceeds its budget. The hardware team delivers prototypes on schedule, but the software team struggles to make them functional, leading to frantic, last-minute debugging cycles.

Diagnosis: This scenario signals a fundamental disconnect between hardware and software development tracks. When these teams operate in silos, integration becomes an afterthought rather than a core design principle. The result is a cascade of predictable issues: software drivers that are incompatible with hardware revisions, timing mismatches between components, and reliability failures that only surface during system-level testing when they are most expensive to fix.

Consider a medical device company developing a next-generation infusion pump. The hardware is state-of-the-art, and the software passes all unit tests. Yet, during verification, the device intermittently fails. The root cause is a subtle timing conflict—a few milliseconds of latency between the sensor data bus and the processor’s read cycle. This is a classic integration flaw that a unified, co-design process would have identified and resolved months earlier, likely at the architectural stage.

The core issue is rarely a lack of engineering talent. It’s a fractured development strategy. Building hardware and software as separate, parallel efforts embeds risk directly into the product’s foundation.

A Solution Focused on Integration and Outcomes

Specialized embedded software development services provide the critical bridge between the physical and digital domains of a product. Engaging a dedicated partner isn’t merely outsourcing a task; it’s a strategic decision to integrate experts who view the system as a single, cohesive unit. This integrated methodology is what enables mission-critical advancements in demanding fields like Industrial Automation and defense.

This partnership model is designed to deliver quantifiable business outcomes:

- Systematic Risk Reduction: By applying principles like Design for Test (DfT) and Design for Manufacturability (DfM) from day one, potential integration failures are engineered out of the system before they can impact the budget and timeline.

- Accelerated Time-to-Market: A cohesive strategy allows hardware bring-up, driver development, and application logic to occur in a tightly coupled, iterative process, not a rigid sequence. This concurrent engineering approach can shorten development cycles by months.

- First-Pass Success: The primary objective is a product that functions as specified reduce integration churn and get to a stable bring-up faster, with fewer respins and less rework. Achieving this eliminates the need for costly and time-consuming board respins and rework, preserving capital and securing market position.

Core Embedded Service Offerings and Their Business Impact

When engaging an embedded software partner, you are not buying lines of code. You are securing a set of specialized capabilities required to translate a hardware design into a reliable, high-performance product. Understanding these services is essential for making informed strategic decisions.

The market scale underscores the criticality of these services. The global embedded systems market is projected to grow from USD 178.15 billion in 2024 to USD 283.90 billion by 2034, with North America commanding a 51% share, driven by intense demand from the automotive, defense, and industrial sectors. For a detailed analysis, see this deep dive on embedded systems from Precedence Research. This growth reflects a core reality: mastering the foundational software is non-negotiable for product success.

Firmware and Low-Level Drivers

Development begins at the lowest level of the software stack with firmware. This is the code permanently stored in a hardware device’s non-volatile memory—the first instructions that execute at power-on. Firmware initializes the processor and peripherals, effectively bringing the silicon to life and establishing the foundation for all higher-level software. Explore the nuances of professional firmware services here.

Working directly with firmware are device drivers. A driver is a specialized software component that serves as a translator, converting high-level commands from an operating system into the precise, register-level instructions a specific piece of hardware—a sensor, motor controller, or radio module—can execute.

Scenario: An agricultural technology firm is developing a smart irrigation system using proprietary soil moisture sensors. An off-the-shelf driver cannot communicate with the custom hardware interface.

Diagnosis: The data bottleneck is a driver-level incompatibility.

Solution: An embedded services partner would develop a custom device driver that implements the sensor’s unique communication protocol.

Outcome: The custom driver enables the main application processor to receive accurate, real-time moisture data, ensuring the system functions efficiently and reliably. The hardware’s unique value is unlocked.

Board Support Packages and Hardware Abstraction

A Board Support Package (BSP) is a collection of software—including the bootloader, device drivers, and kernel modifications—that enables a standard operating system (like Linux or a RTOS) to function on a custom hardware board. A well-architected BSP is the critical link between generic OS code and a specific hardware design.

A robust BSP significantly accelerates the “board bring-up” phase—the critical process of powering on and validating a new hardware prototype. This directly translates to a shorter path from bare PCB to a functional development platform.

A related concept, the Hardware Abstraction Layer (HAL), creates a consistent software interface that decouples the main application from the low-level hardware details. This is a crucial strategic asset for product families, allowing the same application code to run across multiple hardware versions with minimal modification, reducing long-term maintenance costs and improving scalability.

Real-Time Operating Systems

For many embedded products, timing is not just a performance metric; it is a critical safety and functional requirement. A Real-Time Operating System (RTOS) is an OS architected for deterministic task scheduling. Unlike a general-purpose OS that optimizes for average throughput, an RTOS guarantees that high-priority tasks will execute within a defined, predictable deadline, every time.

A missed deadline in a real-time system is a system failure.

- Medical Use Case: An infusion pump must deliver a precise volume of medication at an exact interval. An RTOS ensures the task controlling the pump motor is never preempted by a lower-priority task (like updating the display), eliminating the risk of incorrect dosage.

- Aerospace Use Case: A drone’s flight control system relies on an RTOS to process sensor data from its inertial measurement unit (IMU) and make microsecond adjustments to motor speeds. This deterministic performance is what ensures flight stability.

The following table maps these technical services to their direct business consequences.

Embedded Software Services and Their Business Impact

| Service Offering | Technical Function | Primary Business Impact |

|---|---|---|

| Firmware Development | Provides the core operational code that brings hardware to life. | Product Reliability: Ensures the device boots and functions correctly from the ground up. |

| Device Drivers | Translates OS commands into hardware-specific instructions. | Functionality & Performance: Unlocks the full capability of custom or specialized hardware components. |

| Board Support Package (BSP) | Enables an operating system to run on custom hardware. | Speed to Market: Drastically reduces the time needed for initial hardware prototyping (“board bring-up”). |

| Hardware Abstraction Layer (HAL) | Creates a standard interface between software and hardware. | Scalability & Cost Efficiency: Allows application code to be reused across different hardware platforms. |

| Real-Time Operating Systems (RTOS) | Manages tasks with strict, deterministic timing guarantees. | Safety & Precision: Critical for applications where missed deadlines can cause system failure or harm. |

Engaging a partner with mastery across this stack ensures that the entire system—from power-on to complex application execution—is architected for reliability, performance, and long-term viability.

Navigating the Embedded Development Lifecycle

Misaligned expectations between a client and a development partner are the primary cause of project failure, leading to budget overruns and missed market windows. The solution is not more status meetings; it is a disciplined, transparent development lifecycle that establishes clear objectives, deliverables, and accountability at every stage.

A structured process transforms complex product development from an unpredictable art into a managed science. It systematically de-risks the project by breaking it into distinct, verifiable phases, reducing the management burden on your internal team and creating a predictable path from concept to production.

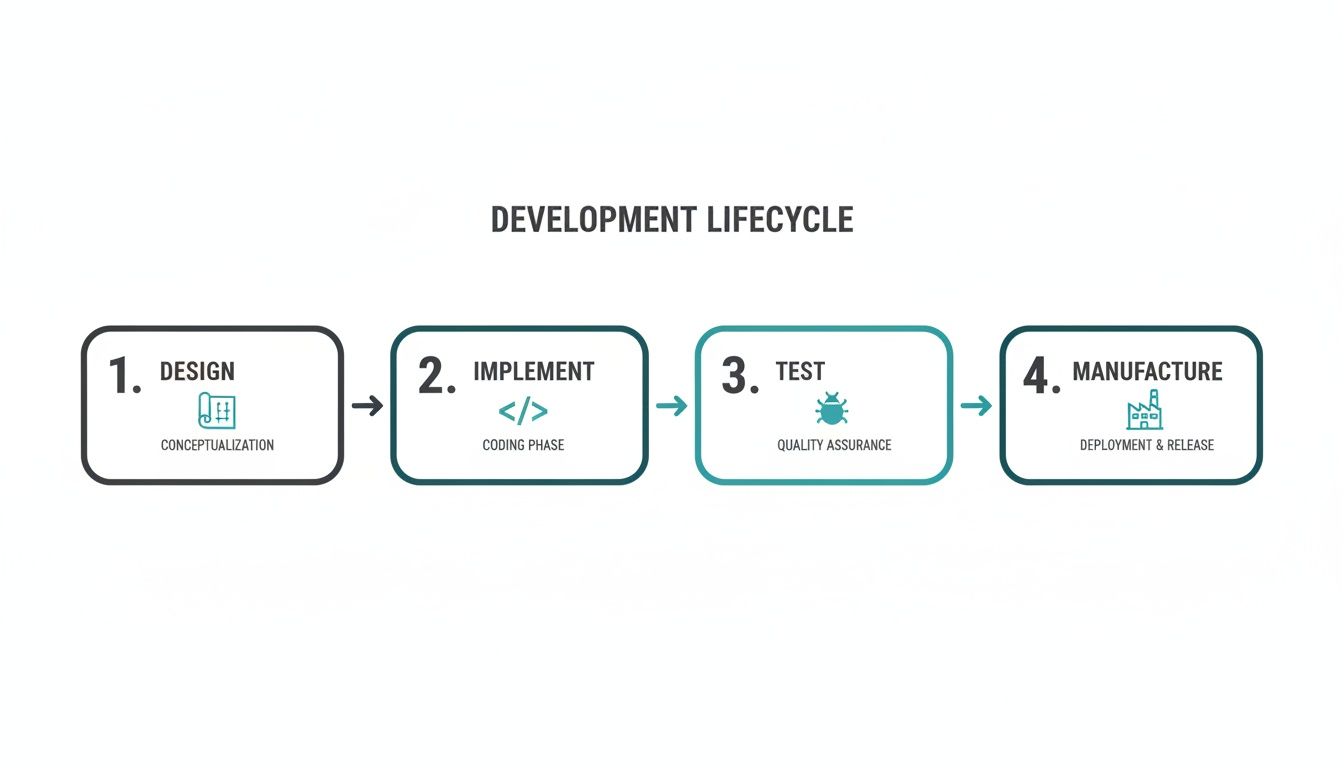

The lifecycle is a logical progression from design and implementation through testing and manufacturing readiness.

Each phase builds upon the last, ensuring that foundational architectural decisions are correctly implemented and validated in the final, manufacturable product.

Phase 1: Requirements Analysis and Architecture Design

This phase begins with a deep analysis of business objectives and technical constraints. The goal is to move beyond a feature list to understand the core problem the product solves, its non-negotiable performance criteria, and its regulatory landscape.

This analysis yields two foundational documents: a System Requirements Specification (SRS) and an Architectural Design Document.

- System Requirements Specification (SRS): This document is the single source of truth for the project. It codifies all functional and non-functional requirements, from performance metrics and power budgets to safety standards and user interface constraints.

- Architectural Design Document: This document translates the SRS into a technical blueprint. It defines the major hardware and software components, selects the OS/RTOS, specifies communication protocols, and outlines the overall system structure. It is the master plan for execution.

A high-impact partner uses this phase to challenge assumptions and ask critical questions, preventing costly architectural changes later in the lifecycle.

Phase 2: Implementation and Integration

With a validated architecture, development begins. This phase involves writing and unit-testing the firmware, device drivers, BSP, and application-level code. A key discipline during this stage is continuous integration (CI), where software modules are frequently merged and tested together.

This iterative approach is designed to identify integration bugs early, preventing the “big bang” failure that often occurs when separately developed components are combined for the first time just before a deadline. Deliverables are tangible and verifiable.

Key Deliverables:

- Verified Code Modules: Each software component is subjected to rigorous unit testing to confirm compliance with its specification.

- Integrated Software Builds: The team produces regular, testable builds of the complete software stack, demonstrating incremental progress and functionality.

- Early Prototypes: Functional hardware prototypes running initial software builds enable early validation of core features and provide a platform for stakeholder feedback.

Phase 3: Rigorous Testing and Verification

While testing is a continuous activity, this phase represents a concentrated quality assurance effort. The objective is to formally validate that the integrated system meets every requirement defined in the SRS.

This involves a multi-layered testing strategy:

- System Integration Testing: Validates that all software and hardware components function correctly as a unified system.

- Performance and Stress Testing: Pushes the device to its operational limits to identify performance bottlenecks, memory leaks, and other weaknesses under load.

- Hardware-in-the-Loop (HIL) Testing: Simulates real-world operating conditions and fault scenarios in a controlled, repeatable lab environment to test the system’s robustness and error handling.

For regulated industries, this phase is critical for generating the documentation required for certification. For example, the testing protocols must align with frameworks like the Medical Device Product Development Process Explained. The outcome is a fully validated product with documented evidence of its reliability and safety, ready for manufacturing handoff.

Choosing the Right Engagement Model

The choice of engagement model is a strategic decision that directly impacts budget, timeline, and risk. Selecting the wrong model introduces friction and misalignment; the right one creates a foundation for a successful partnership.

This decision is increasingly critical. The global embedded software market reached USD 20.7 billion in 2024 and is projected to grow at a 9.6% CAGR through 2034, driven by the relentless demand for connected, intelligent devices. With North America comprising 35% of this market, the pressure to execute complex projects efficiently is immense. Reviewing a comprehensive market analysis from Global Market Insights highlights the trend: how you structure the partnership is as important as the technology itself.

The Fixed-Price Project Model

The fixed-price (or project-based) model is often preferred by leaders focused on budget predictability. The scope, timeline, and deliverables are defined exhaustively upfront, and the partner provides a single price for execution.

This model is effective when requirements are fully understood and static. For projects with a locked-in Product Requirements Document (PRD), stable hardware, and no technical unknowns, a fixed-price engagement provides cost certainty and minimizes management overhead. However, its rigidity is a significant risk.

Problem: An industrial automation client engaged a firm on a fixed-price basis to develop firmware for a new PLC with fully defined specifications.

Diagnosis: Mid-development, a supply chain disruption forced a change to a critical microcontroller. This single hardware substitution invalidated key architectural assumptions and required significant rework of firmware and drivers—all of which was outside the rigid, predefined scope.

Outcome: The project stalled during protracted change-order negotiations. The inflexibility of the model negated any initial cost savings, delayed the product launch by a full quarter, and created significant friction between the teams.

The fixed-price model is poorly suited for projects with any degree of technical ambiguity or evolving requirements.

The Dedicated Team Model

The dedicated team model offers a fundamentally different approach. Instead of purchasing a predefined output, you secure a dedicated block of engineering resources (e.g., two firmware engineers and a QA specialist) for a set period. This model is architected for agility.

It is the optimal choice for R&D initiatives, new product introductions, or any project requiring tight, daily collaboration between your internal team and the external partner. It provides the flexibility to reprioritize work, pivot based on new learnings, and address unforeseen technical challenges without the administrative friction of change orders. The tradeoff is that this model requires more active involvement from your product owner or project manager to guide the team’s priorities.

Making the Right Choice

The correct model depends on an objective assessment of your project’s characteristics. Neither is inherently superior; success lies in matching the model to the reality of the project.

Use this framework for your decision:

- Scope Clarity: Are requirements 100% defined, documented, and stable? A fixed-price model may be viable. Is there any R&D, discovery, or technical uncertainty? A dedicated team is the more effective and lower-risk option.

- Flexibility Needs: Do you anticipate potential hardware revisions, evolving user feedback, or shifting market demands? The agility of a dedicated team is essential to prevent project gridlock.

- Internal Involvement: A fixed-price model requires a significant upfront investment to define every detail. A dedicated team requires continuous engagement from your product manager to set priorities and steer development.

For the majority of complex embedded systems, where discovery and adaptation are inherent to the process, the flexibility of a dedicated team model almost always delivers a higher long-term ROI by preventing costly delays and enabling a superior final product.

How to Evaluate Potential Development Partners

Selecting an embedded software partner is a high-stakes decision. A surface-level evaluation of client lists or technology stacks is insufficient. The right partner operates as a seamless extension of your engineering team; the wrong one can derail your product roadmap. The goal is to identify a partner with deep technical credibility, a proven methodology, and a clear focus on your business objectives.

The stakes are rising. North America’s embedded software market, valued at USD 6.03 billion in 2024, is projected to more than double to USD 13.33 billion by 2033, driven largely by the manufacturing sector’s adoption of Industry 4.0. As demand for smart factories and industrial robotics grows, the quality of your embedded partner will directly determine your competitive position. A full analysis is available in the North America embedded market forecast on MarketDataForecast.com.

Look for a Proactive Approach to Risk Mitigation

An average partner reacts to problems; an exceptional partner anticipates and prevents them. The most significant differentiator is a systematic process for identifying and mitigating risk from the initial engagement. This is where methodologies like Design for Test (DfT) and Design for Manufacturability (DfM) become core operational principles, not just buzzwords.

A partner grounded in DfM will interrogate your supply chain, component selections, and assembly process before writing any code. They understand that sophisticated software is useless if the hardware it runs on cannot be manufactured reliably and at scale.

A partner’s commitment to DfT and DfM is a direct indicator of their maturity. It demonstrates a focus on total cost of ownership and long-term product success, not just the completion of a software task.

Evaluate Their Prototyping and Validation Capabilities

Designs on paper are theoretical. Functional prototypes reveal the truth. A partner with in-house rapid prototyping capabilities can dramatically accelerate the development cycle. The ability to build and iterate on both hardware and software in parallel collapses feedback loops from weeks to days.

Ask potential partners to describe their validation process with a concrete example:

- Scenario: A robotics company is developing an autonomous warehouse drone. The motor control algorithm is performance-critical and must be precisely tuned to the drone’s physical characteristics.

- Average Partner: Develops the software, delivers it, and waits for the client to build a prototype and test it. Each iteration cycle is gated by shipping delays and external dependencies, stretching the feedback loop to weeks.

- Exceptional Partner: While developing the control software, their in-house lab uses 3D printing and quick-turn PCB fabrication to build a functional motor test rig. Engineers can immediately test and refine algorithms on real hardware, reducing the iteration cycle to hours.

This parallel build-and-test capability is a powerful de-risking tool. It uncovers integration issues early and provides a measurable impact on your speed to market. For more on this integrated approach, see our guide on software development consulting services.

Assess Their Technical Credibility and Team Structure

Finally, evaluate the team itself. When a technical issue arises, will you be speaking with a project manager or the principal engineer architecting the solution? True technical credibility means direct access to experts who can diagnose and solve problems in real time.

Look for a partner that provides a single, accountable program lead responsible for the entire system—firmware, hardware integration, and manufacturing liaison. This centralized structure eliminates the communication gaps and finger-pointing that plague complex projects, ensuring a clear and efficient path from concept to production.

Your Game Plan for Finding the Right Partner

Engaging an embedded software partner is a critical strategic decision, not a commodity purchase. A successful engagement accelerates your entire product roadmap, while a poor one introduces delays and cost overruns. To mitigate this risk, replace the generic RFP process with a strategic evaluation designed to build a foundation of clarity and alignment from the start.

Step 1: Ditch the Specs, Define the Outcome

Before detailing technical requirements, define the business outcome. A partner must understand why a product is being built to make the correct architectural tradeoffs.

Do not simply state, “We need firmware for a new sensor.”

Instead, frame the objective: “Our goal is to reduce customer equipment downtime by 30% by introducing a predictive maintenance capability. This requires firmware that can process sensor vibration data and trigger an alert with less than 500ms of latency.”

This shift from a task to a mission focuses the entire engagement on business value, ensuring the partner is solving the right problem.

Step 2: Build Your “Briefing Book”

To receive accurate proposals and accelerate the evaluation process, provide potential partners with the necessary information to perform a thoughtful analysis. A comprehensive briefing package signals that you are a serious client and enables a substantive technical discussion.

Your briefing book should include:

- Product Requirements Document (PRD): Detail core functionality, performance targets (e.g., processing speed, power consumption), and key operational constraints.

- Existing Schematics and BOM: Share all available hardware design files, even if preliminary. This provides critical context for firmware and driver development.

- The Regulatory Gauntlet: Be explicit about compliance standards. Whether it’s IEC 62304 for medical devices or DO-178C for avionics, these requirements dictate the entire development and verification process.

Providing this information upfront acts as a filter. It elicits a detailed, well-reasoned response instead of a generic quote, which is essential when vetting a potential long-term partner.

Step 3: Ask Questions That Reveal, Not Rehearse

Craft questions that probe a partner’s process and problem-solving capabilities, not their marketing claims. The goal is to understand how they manage the inevitable challenges of complex product development.

Focus on scenario-based questions:

- On Risk Mitigation: “Describe a project where a critical component went end-of-life mid-development. How did your team adapt the hardware and software design to keep the project on schedule?”

- On Scope Creep: “Walk me through your process for managing a major requirements change after the architecture has been finalized. How do you assess and communicate the impact on the timeline and budget?”

- On Defining Success: “Beyond delivering functional code, how do you measure the success of an engagement? What key performance indicators do you track to ensure you are delivering business value?”

These questions move the discussion from capabilities to process, accountability, and problem-solving—the core attributes that distinguish a vendor from a strategic partner capable of delivering first-pass success.

Frequently Asked Questions

Decision-makers consistently raise the same critical questions when considering an embedded software partner. Here are direct answers based on field experience.

How Does the Pricing for Embedded Software Services Actually Work?

The cost structure is dictated by the engagement model best suited to the project’s risk profile. For projects with a fully defined and stable scope, a Fixed-Price model provides complete budget predictability.

However, most innovative embedded projects involve discovery and evolution. For these, a Time & Materials model offers the necessary flexibility to adapt to changing requirements. A Dedicated Team model provides a reserved block of engineering resources on a retainer basis, functioning as an integrated part of your team. When evaluating options, focus on total business value, not just the hourly rate. A partner’s ability to accelerate your timeline and de-risk manufacturing provides an ROI that far outweighs a lower initial quote.

The critical metric is total cost of ownership. A modest upfront investment in a partner who designs for manufacturability can prevent multiples of that cost in hardware respins and production delays.

How Is Our Intellectual Property Protected When We Outsource?

IP protection is non-negotiable and must be established before any sensitive information is shared. A reputable partner will require a mutual Non-Disclosure Agreement (NDA) at the outset.

The definitive legal protection resides in the Master Services Agreement (MSA) or Statement of Work (SOW). These contracts must contain explicit clauses stipulating that all intellectual property created during the engagement—including all source code, design files, and documentation—is the sole property of the client. Insist on clear, unambiguous IP assignment language. Partners based in jurisdictions with strong legal frameworks, such as the United States and Canada, generally offer the most robust and enforceable IP protection.

How Can We Be Sure the Final Software Will Be High-Quality and Reliable?

Software reliability is not achieved through final-stage testing; it is the output of a disciplined process embedded throughout the development lifecycle. A high-quality partner integrates quality assurance into every phase.

This multi-layered strategy must include:

- Deep Requirements Analysis: Systematically eliminating ambiguity and conflicting requirements before development begins.

- A Solid Architectural Design: Architecting the system for scalability, fault tolerance, and testability from the start.

- Strict Adherence to Coding Standards: Enforcing established guidelines like MISRA to produce clean, maintainable, and safe code.

- A Multi-Faceted Testing Approach: Employing unit tests for modules, integration tests for components, and hardware-in-the-loop (HIL) simulation to validate system behavior under real-world conditions.

The most reliable indicator of a mature, quality-focused engineering culture is a partner’s commitment to Design for Test (DfT) from the project’s inception. This proactive mindset is what separates a system that merely functions from one that is truly reliable.

Ready to de-risk your next project and accelerate your time-to-market? The team at Sheridan Technologies provides end-to-end embedded systems development with an accountable, expert-led approach. Let’s discuss how to ensure your product’s first-pass success.