Table of Contents

For engineering leaders and product managers, CE marking for electronic equipment is not a bureaucratic hurdle to clear at the end of a project. It is a set of core design constraints that dictate market access to the European Economic Area (EEA). Misinterpreting or deferring these requirements is a primary driver of costly launch delays, budget overruns, and significant business risk.

Attempting to place a product on the EU market without a valid CE mark invites immediate consequences: seizure at customs, mandatory product recalls, and substantial financial penalties. This guide provides a systematic framework for integrating CE marking requirements into the product development lifecycle, transforming compliance from a reactive liability into a strategic advantage.

CE Marking as a Strategic Gateway to the EU Market

Treating CE marking as a final, administrative step is a common but critical failure mode. The root problem is a disconnect between engineering execution and regulatory strategy. This reactive approach almost guarantees late-stage discovery of non-compliance, forcing expensive redesigns and compromising market-entry timelines.

A Framework for De-Risking Market Entry

A structured approach is essential for navigating compliance efficiently.

- Problem: A product is designed and prototyped without early consideration for CE requirements, treating compliance as a final testing gate.

- Diagnosis: Weeks before launch, testing reveals fundamental design flaws—excessive electromagnetic emissions, inadequate electrical safety, or the use of a restricted substance (RoHS).

- Solution: Integrate compliance as a core requirement from the initial design phase. Treat applicable directives and harmonized standards as architectural constraints, informing component selection, PCB layout, and enclosure design from day one. This proactive methodology systematically eliminates risks throughout the development lifecycle.

- Outcome: This integrated approach directly reduces the risk of recalls, accelerates time-to-market, and creates a more robust, reliable product. A device engineered for compliance is inherently a better-engineered device, providing a tangible competitive advantage.

The Business Impact of Non-Compliance

The European Commission actively enforces CE marking across approximately 25 product categories. Electronic equipment is governed by several key mandates, including the Low Voltage Directive (2014/35/EU) and the EMC Directive (2014/30/EU).

Enforcement is not theoretical. In 2023, EU market surveillance authorities flagged 15% of inspected electronic products for CE-related non-conformities. Forward-thinking organizations are transforming compliance into a strategic advantage by using the rigorous EU framework to build superior products.

This guide provides an actionable framework for success:

- Identifying Applicable Directives: Pinpoint which regulations—EMC, LVD, RED, RoHS—govern your specific device.

- Executing Conformity Assessments: Determine the correct path: self-certification versus mandatory Notified Body involvement.

- Building Technical Documentation: Compile an audit-proof Technical File and a legally sound Declaration of Conformity.

Integrating these steps early is critical. For any team navigating the path from prototype to product, these insights will de-risk the process and ensure a successful product launch.

Decoding the Maze of EU Directives and Harmonized Standards

The foundational step in any CE marking strategy is accurately identifying the applicable EU directives. This determination dictates the entire scope of testing, documentation, and conformity assessment. An error at this stage invalidates all subsequent compliance efforts, exposing the business to significant risk of market rejection.

Modern electronic devices rarely fall under a single directive. A correct assessment requires a systematic breakdown of the product’s functionality, components, and intended use environment.

The Four Pillars of Electronics Compliance

For most electronic equipment, the analysis begins with four principal directives. A thorough understanding of their scope is non-negotiable.

- Electromagnetic Compatibility (EMC) Directive (2014/30/EU): Applies to nearly all electronic devices. It mandates two conditions: the device must not generate electromagnetic emissions that interfere with other equipment, and it must possess sufficient immunity to operate as intended in its specified electromagnetic environment.

- Low Voltage Directive (LVD) (2014/35/EU): Addresses health and safety risks for electrical equipment operating within specific voltage limits: 50 to 1,000 V for alternating current (AC) and 75 to 1,500 V for direct current (DC). If a product is mains-powered or uses a mains-connected adapter, the LVD is almost certainly applicable.

- Radio Equipment Directive (RED) (2014/53/EU): Governs any device that intentionally transmits or receives radio waves for communication or radiodetermination (e.g., Wi-Fi, Bluetooth, cellular, GPS). RED is comprehensive, incorporating its own requirements for health, safety, and EMC, which often supersede the standalone LVD and EMC directives for the radio-related aspects of the device.

- Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU): Restricts the use of ten specific hazardous materials in electrical and electronic equipment. RoHS compliance is mandatory and requires rigorous supply chain management to ensure all components, down to the solder and cabling, adhere to strict substance limits.

Key EU Directives for Electronic Equipment

| Directive (Number) | Core Requirement | Typical Equipment Covered | Example Harmonized Standard |

|---|---|---|---|

| EMC (2014/30/EU) | Must not interfere with other devices and must be immune to typical interference. | Any electronic device: industrial controllers, home appliances, LED drivers. | EN 55032 (Emissions) |

| LVD (2014/35/EU) | Ensures protection against electrical, mechanical, and other hazards. | Mains-powered devices: power supplies, kitchen appliances, IT equipment. | EN 62368-1 (AV/IT Safety) |

| RED (2014/53/EU) | Ensures effective use of radio spectrum, EMC, and user safety. | Devices with wireless comms: smartphones, IoT sensors, Bluetooth speakers. | EN 300 328 (2.4 GHz) |

| RoHS (2011/65/EU) | Restricts the use of 10 hazardous substances (e.g., lead, mercury, cadmium). | Virtually all electrical and electronic equipment. | EN IEC 63000:2018 |

This table serves as an initial reference. Always consult the official directive text and the current list of harmonized standards in the Official Journal of the European Union (OJEU) for definitive applicability.

Real-World Scenario: A Wirelessly Connected Industrial Sensor

- Problem: Define the compliance and testing strategy for a new battery-powered industrial sensor that uses Bluetooth to monitor machine vibrations.

- Diagnosis: A functional breakdown identifies the applicable directives:

- RoHS (2011/65/EU): Applies as it is an electronic device.

- EMC (2014/30/EU): Applies to the non-radio electronic circuitry to ensure it can function reliably in an electrically noisy industrial environment.

- RED (2014/53/EU): Applies due to the Bluetooth radio. This directive covers the radio’s performance, safety, and EMC aspects.

- LVD (2014/35/EU): Does not apply, as the device is battery-powered and operates well below the LVD’s voltage thresholds.

- Solution: The compliance plan is scoped to require RoHS material declarations, full EMC testing on the complete system, and a suite of radio performance, spectrum, and safety tests under RED.

- Outcome: This upfront analysis yields a precise test plan, ensuring the collection of necessary evidence for the Technical File and the accurate, legally defensible execution of the Declaration of Conformity.

The Strategic Value of Harmonized Standards

Once directives are identified, the question becomes how to demonstrate conformity. Harmonized standards are the most efficient and lowest-risk method. These are technical specifications developed by European standards bodies (CEN, CENELEC, ETSI) and cited in the OJEU.

Adhering to a relevant harmonized standard provides a presumption of conformity with the essential requirements of the directive it supports. This is the clearest and most direct path to compliance, removing ambiguity and providing a regulator-accepted benchmark.

For the industrial sensor, testing to EN 55032 for emissions provides a presumption of conformity with the EMC directive’s emission requirements. While alternative methods exist, they shift the burden of proof entirely onto the manufacturer to demonstrate equivalence, inviting greater scrutiny and adding cost and time. For the vast majority of products, exclusive reliance on harmonized standards is the only prudent business decision.

Choosing Your Conformity Assessment Strategy

After identifying applicable directives, the next strategic decision is selecting the conformity assessment procedure. This choice directly impacts budget, timeline, and risk profile. The central question for any product leader is determining when self-certification is sufficient and when the involvement of a Notified Body is mandatory.

An incorrect assessment path can be catastrophic. A flawed self-declaration can invalidate the CE mark, triggering product recalls and fines. Conversely, unnecessarily engaging a Notified Body introduces significant cost and can delay market entry by months.

Self-Certification vs. Notified Body Involvement

For electronic equipment, the conformity assessment path typically falls into one of two categories.

- Self-Certification (Module A – Internal Production Control): This is the predominant route for products covered by the EMC and LVD directives. The manufacturer assumes full responsibility for conducting tests against harmonized standards, compiling the Technical File, and issuing the EU Declaration of Conformity (DoC). This path is faster and less expensive but places the entire legal burden of compliance on the manufacturer.

- Notified Body (NB) Involvement (Various Modules): For certain higher-risk or novel equipment, engagement with a Notified Body—an independent organization designated by an EU member state—is mandatory. This is often the case for radio equipment under RED, particularly when harmonized standards are not applied to cover all essential requirements. It is also required for many medical devices, industrial machinery, and personal protective equipment.

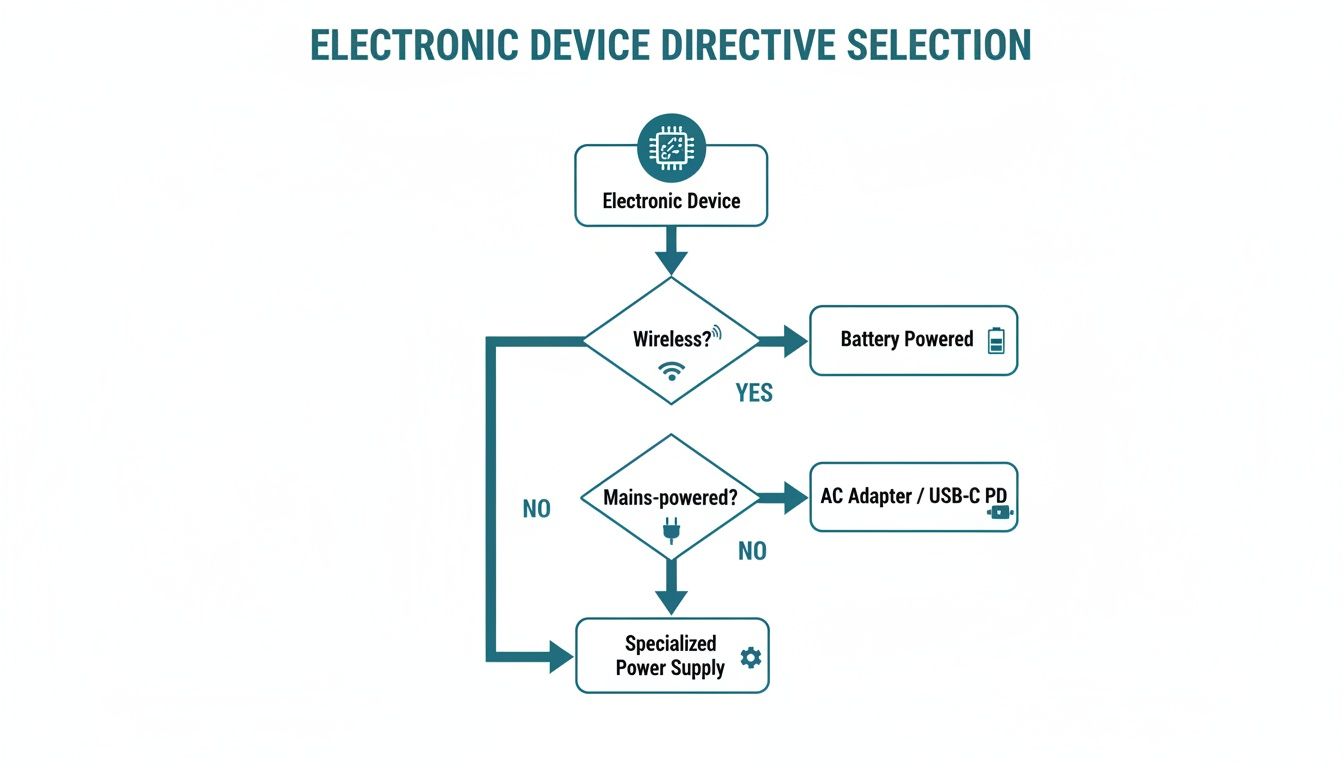

The decision path is often determined by the product’s features, as illustrated below.

The inclusion of a radio transmitter under the Radio Equipment Directive (RED) introduces specific assessment rules that can necessitate a Notified Body review.

Real-World Use Case: A Connected IoT Device

- Problem: Determine the correct conformity assessment path for a new mains-powered smart home hub incorporating Wi-Fi and Zigbee radios.

- Diagnosis:

- Directives: The hub is subject to RoHS, EMC, LVD (mains-powered), and RED (Wi-Fi and Zigbee radios).

- Assessment Path: Self-declaration is permissible for LVD and EMC. However, RED presents a critical choice. If the radio implementation is novel or does not fully align with harmonized standards (e.g., a custom antenna design), a Notified Body EU-Type Examination (Module B) becomes mandatory.

- Solution: The engineering team makes a strategic design decision to use pre-certified Wi-Fi and Zigbee radio modules. These modules have already undergone full testing against RED harmonized standards by the module manufacturer. By integrating them according to the manufacturer’s explicit instructions, the team can leverage the module’s existing conformity evidence. This allows them to self-certify the final product by performing EMC and LVD tests on the complete system and incorporating the radio module certificates into their Technical File.

- Outcome: This design choice avoids the $10,000 – $20,000+ cost and 3-6 month delay associated with a Notified Body review of the radio implementation. The company retains control of its launch schedule, reduces direct compliance costs, and fulfills all legal obligations.

The critical insight is that early architectural decisions directly shape the compliance strategy. Utilizing pre-certified components and adhering strictly to harmonized standards are the most effective tactics for de-risking the conformity assessment process.

This approach integrates compliance into the design workflow, which is the most efficient and cost-effective method of operation. If your team is evaluating the optimal path for a new product, a targeted consultation can provide the necessary clarity. Contact Sheridan Technologies for an expert assessment of your product’s compliance requirements.

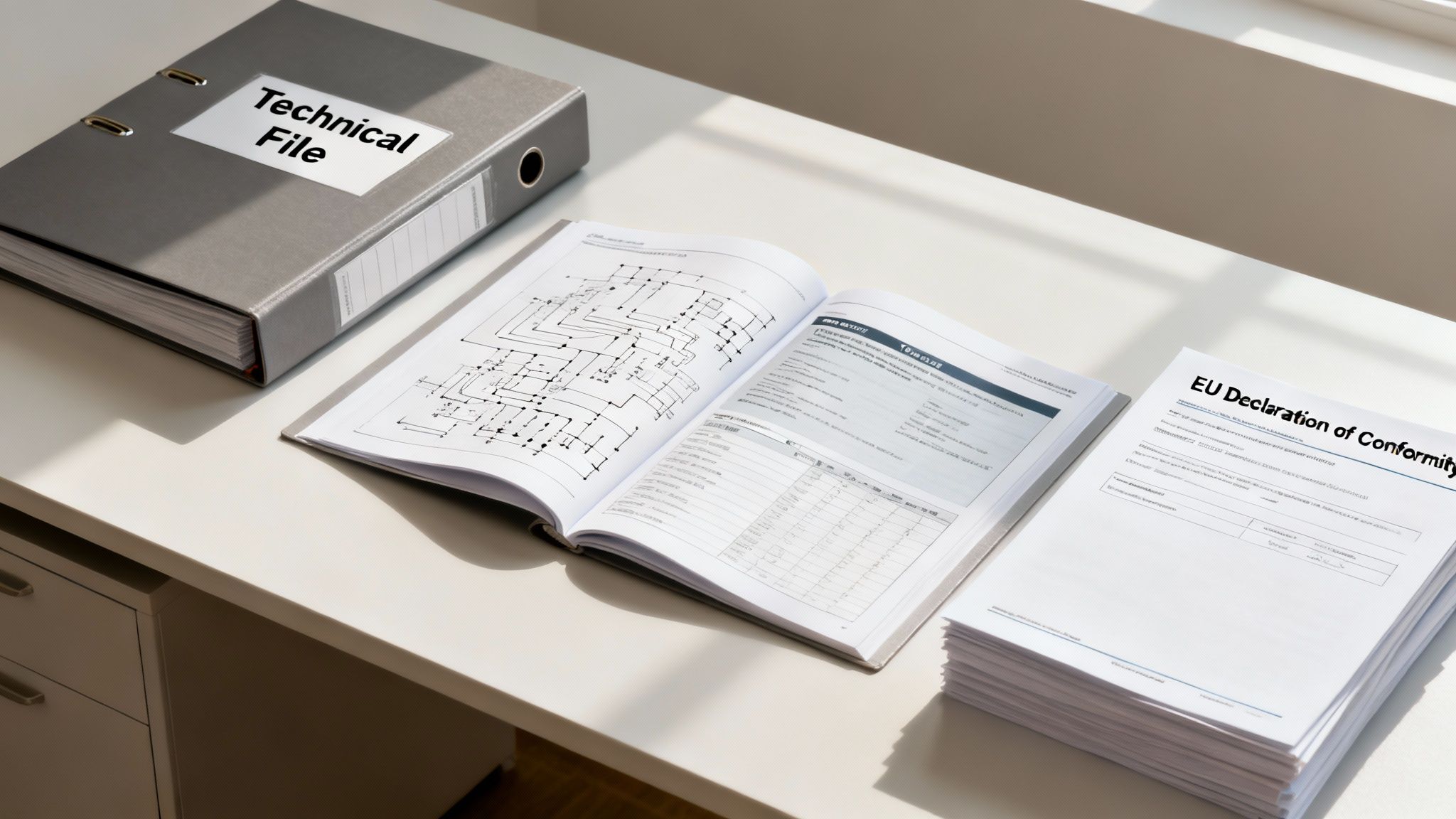

Building Your Audit-Proof Technical File

The Technical File is the definitive body of evidence proving your product meets all applicable CE marking requirements. It is not administrative paperwork; it is the primary document subject to review by EU market surveillance authorities. An incomplete, disorganized, or unsubstantiated Technical File can invalidate your CE mark and expose your business to significant legal and financial risk.

A common failure mode is treating the Technical File as a post-development task. This reactive approach often results in a file that fails to demonstrate a clear link between design choices, risk mitigation, and conformity verification. The only robust method is to build the file concurrently with the product development lifecycle.

Core Components of a Robust Technical File

The Technical File must contain sufficient detail for an auditor to independently understand the product’s design, operation, and the basis of its conformity claims. While specific contents vary by directive, a file for any electronic product must include:

- Product Description and Operation: General description, model numbers, intended use, and functional specifications.

- Design and Manufacturing Drawings: Electrical schematics, PCB layouts, mechanical drawings, and a complete bill of materials (BOM).

- Risk Assessment: A documented analysis of all potential hazards (electrical, mechanical, thermal, etc.) and the specific design measures and standards (e.g., EN 62368-1) applied to mitigate those risks.

- List of Applied Standards: An explicit list of all harmonized and other standards applied, specifying the exact version used for design and testing.

- Test Reports and Calculations: Complete, unedited reports from accredited laboratories for all EMC, LVD, RED, and RoHS testing. For insights on testing practices, see our guide on how to test a circuit board.

- Supplier Declarations and Component Datasheets: Conformity documentation for critical components, such as power supplies or pre-certified radio modules.

- User Manual and Labeling: Final versions of the user manual, installation guides, and all on-product and packaging labels, including the CE mark itself.

The Declaration of Conformity: A Legally Binding Commitment

The EU Declaration of Conformity (DoC) is the capstone of the process. It is a single, formal document in which the manufacturer, through a senior executive’s signature, attests that the product fulfills all relevant EU requirements.

The signature on the DoC transfers full legal responsibility for the product’s compliance to the manufacturer. An inaccurate or fraudulent DoC can lead to severe penalties, including fines and product withdrawals.

Common errors that invalidate a DoC include:

- Incorrectly Listing Directives: Omitting applicable directives or including irrelevant ones.

- Citing Superseded Standards: Referencing outdated versions of harmonized standards.

- Vague Product Identification: Failing to unambiguously identify the specific product model(s) covered.

The objective is to create a documentation package that presents a clear, consistent, and verifiable narrative of compliance, from initial design through final testing, culminating in the legally binding DoC.

Bracing for the Next Wave: Cybersecurity and Sustainability Mandates Are Coming

The CE marking framework is not static; it evolves to address emerging technological and societal risks. For decision-makers, anticipating these changes is essential for maintaining market access and avoiding disruptive, late-stage product redesigns. Two significant shifts—cybersecurity and sustainability—are poised to redefine compliance requirements for nearly all electronic equipment.

Proactively integrating these forthcoming requirements into your development roadmap provides a significant competitive advantage and mitigates the risk of being caught unprepared by new regulations.

The RED Cybersecurity Mandate

A delegated act under the Radio Equipment Directive (RED) will impose mandatory cybersecurity requirements on applicable radio equipment placed on the market after August 1, 2025.

This mandate extends CE marking into the realm of software and network security. Any product with wireless connectivity will need to demonstrate built-in digital safeguards. The act introduces three essential requirements:

- Article 3(3)(d): Will not harm the network or misuse network resources.

- Article 3(3)(e): Ensures protection of personal data and privacy.

- Article 3(3)(f): Includes features to minimize the risk of monetary fraud.

This represents a paradigm shift from CE marking’s traditional focus on electrical safety and EMC. It places firmware and software architecture under direct regulatory scrutiny.

Problem: The proliferation of insecure connected devices creates systemic risks for network infrastructure and personal data. Solution: The EU is making baseline cybersecurity a prerequisite for market entry, compelling manufacturers to adopt a security-by-design approach.

The implications are significant. This delegated act to Directive 2014/53/EU is projected to affect over 80% of new wireless products. A 2024 EU Commission pilot study found that 62% of radio products failed initial cybersecurity assessments, revealing a substantial compliance gap.

Engineering teams must now familiarize themselves with standards such as ETSI EN 303 645, which defines baseline security provisions for consumer IoT. This directly impacts the need for robust security in embedded systems, covering secure boot, encrypted communications, and vulnerability management. Context on broader European data rules, such as why EU data sovereignty matters, is also crucial.

The EU Batteries Regulation and Sustainability

The EU Batteries Regulation (2023/1542) integrates sustainability and circular economy principles directly into the CE marking framework for any product containing batteries.

This regulation replaces a previous, less stringent directive and mandates that batteries themselves must now be CE marked, creating new obligations for product designers and their supply chains. Key requirements include:

- Carbon Footprint Declarations: For many battery types, manufacturers must calculate and declare the total lifecycle carbon footprint.

- Recycled Content Quotas: Minimum thresholds for recycled cobalt, lead, lithium, and nickel in new batteries are mandated, with these targets increasing over time.

- Battery Management Systems (BMS): Certain battery categories require a BMS capable of monitoring and reporting state of health and expected lifetime.

- Replaceability: Portable batteries in appliances must be designed for easy removal and replacement by the end-user, directly challenging the trend of sealed-unit designs.

These sustainability mandates require deeper supply chain engagement. Battery selection can no longer be based solely on technical performance; it now requires verifiable documentation on material sourcing and manufacturing footprint.

Your Next Steps

- Conduct a Cybersecurity Gap Analysis: For any wireless product, assess current designs against the requirements of ETSI EN 303 645 to identify compliance gaps.

- Engage Your Battery Supply Chain: Initiate discussions with battery suppliers regarding their compliance roadmap for Regulation (EU) 2023/1542. Request carbon footprint and recycled content data now.

- Update Your Product Roadmap: Factor the necessary design modifications for both cybersecurity and battery replaceability into the next development cycle.

Waiting for these regulations to take full effect is a high-risk strategy. Addressing these emerging CE marking requirements today will secure a competitive advantage and ensure uninterrupted access to the EU market.

Navigating evolving compliance requirements presents significant challenges. Sheridan Technologies offers targeted consultations to assess the impact of these new cybersecurity and sustainability rules on your product roadmap, helping you build a proactive strategy to stay ahead of regulatory change.

Your Go-To-Market Compliance Checklist

A systematic, repeatable process is essential for translating compliance strategy into successful execution. This go-to-market checklist provides a framework for product managers and engineering leads to manage risk, control costs, and ensure a smooth launch by breaking down the ce marking requirements for electronic equipment into actionable phases.

Phase 1: Pre-Launch Diligence

Actions taken during the design and sourcing phase have the greatest impact on controlling downstream costs and timelines.

- Product Classification and Directive Mapping: Formally document the product’s intended use and technical specifications. Based on this, generate a definitive list of all applicable EU Directives (EMC, LVD, RED, RoHS) and relevant sector-specific regulations. Business Impact: Prevents incorrect testing and ensures the legal foundation of the Declaration of Conformity is sound.

- Supplier Compliance Verification: Actively request and review Declarations of Conformity and supporting technical data for critical components, especially power supplies and pre-certified radio modules. Business Impact: Mitigates significant supply chain risk and prevents inheriting non-compliance that could force a product recall.

Phase 2: Execution and Validation

This phase focuses on generating the objective evidence required to substantiate compliance claims through rigorous testing and documentation.

- Establish a Formal Documentation Plan: Create a centralized repository for the Technical File from the project’s inception. Assign ownership for collecting schematics, risk assessments, test reports, and manuals as they are developed. Business Impact: Builds an audit-proof file incrementally, avoiding a last-minute scramble and ensuring readiness for any surveillance audit.

- Schedule Pre-Compliance Testing: Conduct informal EMC and RF scans on mature prototypes at a test lab. Business Impact: Identifies and resolves critical design flaws when the cost of iteration is low, potentially reducing final certification costs by up to 50% and preventing schedule-destroying failures.

The 2023 EU Batteries Regulation adds a new critical component to this phase, requiring CE marking for all batteries. This introduces complex new requirements for carbon footprint declarations, recycled content verification, and user-replaceability. More details can be found on the new EU battery regulations on z2data.com.

Phase 3: Market Readiness and Surveillance

Compliance is an ongoing obligation that extends beyond the product launch.

- Finalize Labeling and the Declaration of Conformity (DoC): Meticulously verify all markings on the product, packaging, and manual for accuracy. Once validated, ensure the DoC is signed by an authorized company representative. Business Impact: This formal act of accepting legal responsibility is what permits market placement and helps avoid fines or shipment seizures due to labeling errors.

- Implement Post-Market Surveillance (PMS) Protocols: Establish a formal process for monitoring in-field product performance, tracking customer safety feedback, and staying abreast of regulatory updates that could affect compliance status. Business Impact: Fulfills the legal duty to monitor the product and enables a rapid, effective response to any emerging safety or compliance issues.

This checklist can reveal unforeseen risks in your design, supply chain, or documentation. To ensure your go-to-market strategy is robust, book a complimentary assessment with Sheridan Technologies. We help identify compliance gaps before they become critical business problems.

Common Questions from the Field

Navigating the specifics of CE marking often raises critical operational questions for product development teams. Here are concise answers to common queries.

How Long Does This Whole CE Marking Thing Actually Take?

The timeline is dictated entirely by product complexity and the applicable conformity assessment route.

For a simple electronic device subject only to the EMC and LVD directives (where self-certification is permitted), a typical timeline is 6 to 10 weeks, encompassing testing and documentation assembly.

For complex products requiring mandatory Notified Body involvement (e.g., certain radio equipment, medical devices, or machinery), the process can extend from 6 months to over a year.

The most common delays are caused by failed EMC tests or an incomplete Technical File, both of which can force costly redesigns. The most effective way to control the timeline is to integrate compliance planning into the design process from the outset.

What Happens if We Just Slap a CE Mark on It?

Affixing a CE mark without completing the required conformity assessment procedures is a serious violation of EU law. Market surveillance authorities in any member state have the power to demand the Technical File for inspection at any time.

If a product is found to be non-compliant, the consequences are severe:

- Mandatory product recall across the entire EEA.

- Substantial fines, which can range from thousands to millions of euros.

- In cases of gross negligence resulting in harm, imprisonment of responsible individuals is a potential outcome.

The reputational damage from such an event can be irreversible. The Declaration of Conformity must not be signed until all procedures are complete and documented.

Can We Use Test Reports from a Lab Outside the EU?

Yes, this is often permissible, but with critical caveats.

Test reports from a non-EU laboratory are generally acceptable provided the lab is accredited to ISO/IEC 17025 for the specific tests performed and has tested against the current, correct EU harmonized standards. Accreditation under the ILAC Mutual Recognition Arrangement (MRA) provides an additional layer of international acceptance.

However, if your product requires mandatory assessment by a Notified Body (e.g., under the RED), that Notified Body has the final say. They reserve the right to reject reports from laboratories they have not personally audited or approved. They may require witnessed testing or demand that all tests be repeated.

The critical action: If a Notified Body is required, engage with them early in the process. Confirm their list of accepted test laboratories before commissioning any testing to avoid costly and time-consuming rework.

Identifying and mitigating compliance risks before they impact your launch schedule and budget is paramount. The expert teams at Sheridan Technologies provide comprehensive assessments to ensure your product has a clear and efficient path to the EU market. Schedule a consultation to de-risk your next product launch.