Table of Contents

An effective industrial IoT solution is not a collection of connected sensors; it is an engineered system of hardware, software, and operational expertise designed to solve high-stakes problems on the factory floor, in the field, or across a supply chain.

These solutions are architected to convert high-volume machine data into tangible business outcomes: reducing downtime, improving asset performance, and enhancing workplace safety. This is where IIoT transitions from a technological concept to a driver of measurable P&L impact.

What Defines a Modern Industrial IoT Solution

For leaders and operators, the term ‘IIoT’ can be frustratingly vague, often leading to stalled pilot projects and budget overruns. The most common failure mode is treating an industrial IoT solution as a single, off-the-shelf product.

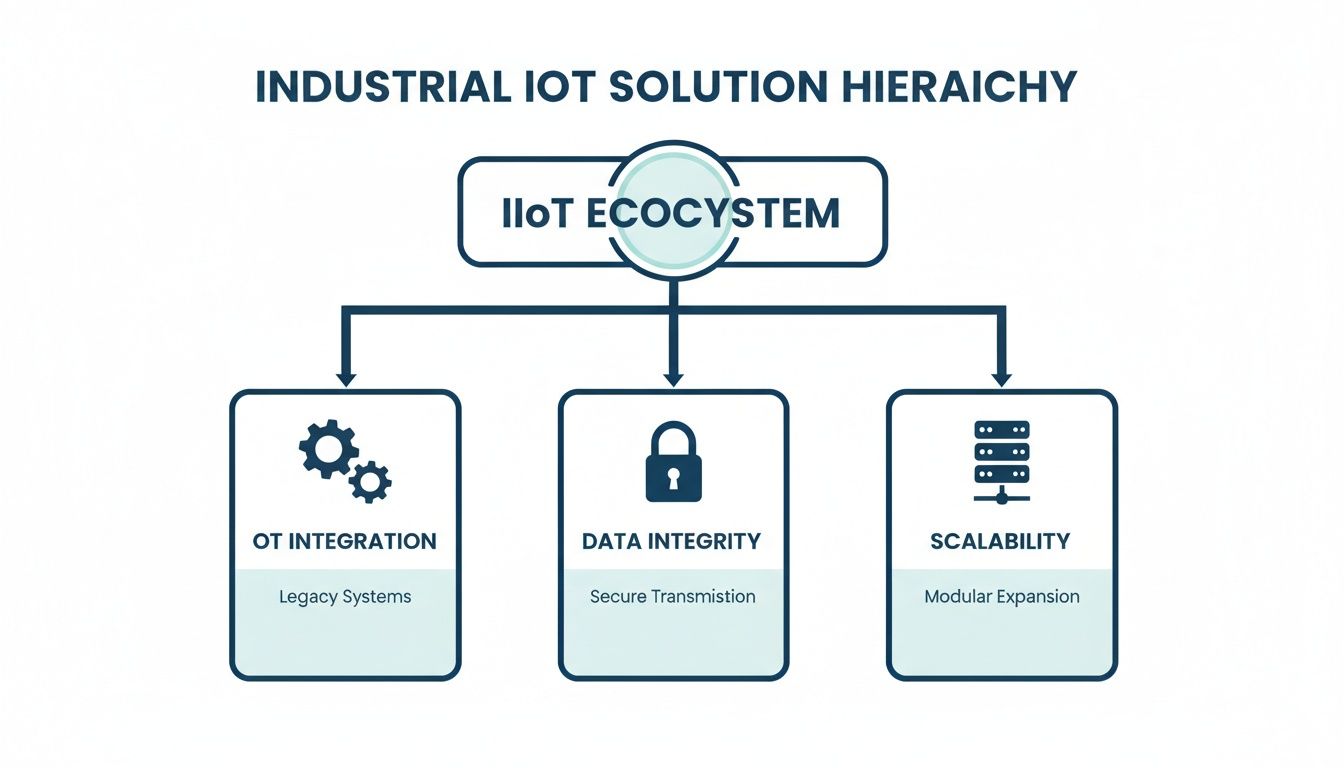

In reality, a successful IIoT deployment is a purpose-built system designed to bridge the critical gap between physical machinery—the domain of Operational Technology (OT)—and enterprise IT systems.

Integrating these two worlds requires a structured framework. Without one, initiatives fail, producing unreliable data and hitting a scalability wall. The objective is not just to collect data, but to guarantee its integrity from the sensor to the boardroom.

The Four Pillars of a Successful IIoT Initiative

To withstand the demands of an industrial environment, a modern IIoT solution must be built on four non-negotiable principles:

- Operational Technology (OT) Integration: The system must communicate fluently and securely with existing equipment. This means native support for industrial control systems (ICS), PLCs, and legacy machinery using protocols like Modbus, OPC-UA, or BACnet/IP. This is essential for acquiring accurate data without disrupting production.

- End-to-End Data Integrity: Data trustworthiness is paramount. Each device must be securely authenticated, data must be encrypted in transit (e.g., via TLS/DTLS), and data pipelines must be continuously validated. Every automated alert and executive report depends on this foundation.

- High-Availability System Design: Industrial operations demand constant uptime. The solution must be engineered for extreme resilience, incorporating hardware redundancy, software failover mechanisms, and edge computing to maintain critical functions during network outages.

- Scalable Architecture: A solution that works for one asset must be architected to support a fleet of thousands. This typically requires a flexible, cloud-native infrastructure designed from day one to handle exponential data growth without requiring a complete re-architecture.

An effective industrial IoT solution is not defined by its technological novelty but by its ability to reliably solve a specific operational problem—like preventing a critical motor failure or optimizing facility-wide energy consumption—at scale.

Market data validates this focus on tangible outcomes. The global industrial IoT market was valued at approximately USD 514.39 billion in 2025 and is projected to reach USD 2,146.07 billion by 2034. Manufacturing leads this adoption, accounting for 28.7% of the market, as companies prioritize production optimization and predictive maintenance.

You can examine the data in the latest IIoT market growth analysis on Precedence Research. This growth signals a clear shift: the era of IIoT experimentation is over, replaced by strategic, ROI-driven deployment.

A Practical IIoT Architecture: Layers, Tradeoffs, and Failure Modes

A real-world Industrial IoT solution is a multi-layered system engineered for performance under pressure. Understanding this architecture is critical for evaluating vendor proposals and avoiding systems that collapse under real operational stress.

A resilient IIoT architecture is typically composed of five distinct layers, each with a specific function and unique failure modes.

This structure functions as a nervous system for an industrial operation. Sensors act as nerve endings, the network is the spinal cord, and processing centers function as the brain—all orchestrated to trigger intelligent, automated actions.

The Five Layers of an IIoT System

A well-designed IIoT system ensures data flows smoothly and securely from a machine on the factory floor to a business application. This requires each layer to execute its function and hand off data reliably to the next.

- Perception Layer (The Edge): Where the physical and digital worlds meet. It comprises sensors that measure physical properties (temperature, vibration, pressure) and actuators that perform physical tasks (closing a valve, adjusting motor speed).

- Transport Layer (Connectivity): Responsible for data movement. This layer includes gateways that aggregate sensor data and networking technologies—Wi-Fi, Ethernet, cellular, private 5G—that transmit it.

- Processing Layer (Compute): Where raw data is analyzed. This occurs at the edge (edge computing) for low-latency decisions or in the cloud (cloud computing) for large-scale analytics and long-term storage.

- Application Layer (The Platform): Where data is translated into actionable information for users. IIoT platforms provide the software for dashboards, alerts, and management tools.

- Business Layer (Integration): The final stage, where IIoT insights connect to core business systems. Data flows into Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES) to automate workflows, such as generating a maintenance work order based on a predicted equipment failure.

This diagram illustrates how a complete IIoT ecosystem depends on tight OT integration, robust data integrity, and a scalable architecture to generate business value.

Without a strong foundation in these three areas, any IIoT project will struggle to scale or produce the trustworthy intelligence required for effective decision-making.

Analyzing Critical Tradeoffs and Failure Modes

Building a resilient system requires anticipating what can go wrong. While each layer presents challenges, the primary architectural decision is where to process data.

The most critical tradeoff is between edge and cloud computing.

- Edge Computing is mandatory for applications requiring near-instantaneous response. A robotic arm’s safety controller, for example, cannot tolerate the latency of a round trip to the cloud. Local processing ensures hard real-time response, where any delay constitutes system failure. The constraint is the limited compute power and storage available at the edge.

- Cloud Computing offers virtually unlimited compute power and storage, ideal for analyzing years of fleet-wide data to build predictive maintenance models. The primary failure point is network connectivity; if the connection is lost, data processing halts. This is acceptable for soft real-time systems where minor delays are not catastrophic.

The decision of where to compute—at the edge or in the cloud—is not a technology choice but a business one. It must be dictated by the operational requirements of the use case, balancing the need for speed against the power of large-scale analytics.

Failure can also occur elsewhere. At the perception layer, sensor drift can gradually corrupt data, leading to false alarms or missed events. In the transport layer, network latency or packet loss can cripple systems dependent on timely information.

To build an architecture that scales and withstands these failures, many organizations adopt Microservices Architecture Best Practices at the application and business layers. A properly designed architecture plans for these risks with built-in redundancy, data validation, and failover logic to ensure the industrial IoT solution remains operational even when individual components fail.

The IIoT Platform and Component Landscape

Choosing the right Industrial IoT platform is a high-stakes decision with long-term financial and operational consequences. The path chosen today will define the capabilities, scalability, and total cost of ownership of your entire IIoT program for years.

The decision distills down to a classic engineering dilemma: build a custom platform from scratch or buy a Commercial-Off-the-Shelf (COTS) solution?

This is a strategic choice, not just a technical one. A misstep can lead to vendor lock-in, significant budget overruns, or a system that cannot scale with operational growth. The challenge is to balance immediate needs with long-term flexibility.

Build vs. Buy: The Central Tradeoff

The build-or-buy decision requires a sober assessment of your organization’s core competencies, capital availability, and the uniqueness of your operational requirements. Neither path is universally superior; each carries significant tradeoffs.

Building a custom IIoT platform provides maximum control and customization. Every feature can be tailored to specific workflows and integrated deeply with proprietary systems. However, this path requires a substantial upfront investment in a specialized development team, ongoing maintenance costs, and a longer time-to-market. The risk of failure is also higher, as you own the entire technology stack, from device firmware to cloud infrastructure. For more on this complexity, see our guide on embedded software development services, the foundation of custom IIoT hardware.

Buying a COTS platform accelerates deployment and reduces initial development costs. These platforms are purpose-built for industrial use cases and come with pre-configured tools for device management, data visualization, and analytics. The primary risks are vendor lock-in and customization limitations. If the platform’s roadmap diverges from your needs, you may face a costly and disruptive migration.

A pragmatic approach often lies in a hybrid model. Many successful projects leverage a COTS platform for commodity functions—like device management and data ingestion—while building custom applications on top to handle unique business logic and user interfaces. This balances speed and cost-effectiveness without sacrificing critical customization.

The market for COTS platforms is expanding rapidly, reflecting the demand for integrated solutions. The global IIoT platform market was valued at USD 11.11 billion in 2025 and is projected to reach USD 30.33 billion by 2033, growing at a 13.41% CAGR. You can find more insights about the industrial IoT platform market on SNS Insider.

Interoperability: The Critical Role of Industrial Standards

Whether you build or buy, a siloed system is a dead end. Your IIoT platform must communicate seamlessly with a diverse range of industrial equipment, from modern machines to legacy systems. Adherence to open industrial standards is non-negotiable.

An effective industrial IoT solution is built on protocols designed for OT environments. Key standards to require in any platform include:

- OPC-UA (Open Platform Communications Unified Architecture): The de facto standard for secure, platform-independent communication on the factory floor. It is essential for interfacing with modern PLCs, SCADA systems, and other controllers while preserving critical data context.

- MQTT (Message Queuing Telemetry Transport): A lightweight and efficient messaging protocol ideal for resource-constrained devices and unreliable networks. Its publish/subscribe model excels at sending sensor data to the cloud with minimal bandwidth.

By ensuring your chosen platform and components support these standards, you create a flexible and future-proof IIoT ecosystem. This approach avoids vendor lock-in and provides the freedom to integrate best-in-class hardware and software as your requirements evolve.

From Theory to Impact: Real-World Use Cases

Architectural diagrams only tell part of the story. The value of an Industrial IoT solution is demonstrated in high-stakes environments where a single failure has immediate and significant consequences. It is in these contexts that IIoT proves its worth, evolving from a concept to a core driver of business resilience and profitability.

We will examine two distinct scenarios: maintaining a high-volume manufacturing line and ensuring the structural integrity of a modern aircraft. Each follows a clear path from operational problem to measurable business impact.

Use Case 1: Predictive Maintenance for CNC Machines in Manufacturing

Problem: A Tier 1 automotive supplier experienced frequent, unplanned downtime on its CNC machining lines due to catastrophic spindle failures. A failure not only halted a single machine but disrupted the entire production line for hours, often scrapping the in-process part and derailing production schedules. Reactive maintenance and fixed-schedule replacements were proving costly and ineffective.

Diagnosis: The maintenance team lacked visibility into the subtle indicators of component degradation. Imperceptible increases in micro-vibrations and the slow creep of bearing temperatures were invisible precursors to catastrophic, line-stopping failures.

Solution: A targeted industrial IoT solution was deployed on the most critical CNC machines.

- Sensing: High-frequency accelerometers were mounted on spindle housings to detect minute changes in vibration signatures. Thermal sensors continuously monitored bearing temperatures.

- Edge Computing: An industrial gateway on each machine processed this high-frequency data locally, performing real-time analysis to identify immediate anomalies requiring an emergency shutdown (millisecond response).

- Cloud Analytics: Sensor data was transmitted to a cloud platform where a machine learning model, trained on historical failure data, analyzed long-term trends. The model learned to identify the specific vibration and thermal signatures that preceded spindle failure.

Outcome: The system began providing the maintenance team with a 72-hour advance warning of probable spindle failures. This enabled them to schedule repairs during planned downtime, eliminating unplanned production stoppages. The business impact was a 15% increase in Overall Equipment Effectiveness (OEE) and a 22% reduction in maintenance-related downtime within the first year. This is the essence of modern industrial automation—using intelligent data to drive operational excellence.

Use Case 2: Structural Health Monitoring in Aerospace

Problem: For an airline, inspecting large composite airframes for subsurface delamination or micro-fractures is a time-consuming and expensive process. Traditional non-destructive testing (NDT) methods require grounding aircraft for extended periods, directly impacting fleet availability and revenue.

Diagnosis: Without continuous monitoring, potential structural issues could only be detected during major, scheduled teardown inspections. This reactive approach carried both significant financial costs and inherent safety risks.

Solution: A sophisticated IIoT solution was integrated directly into the airframe during manufacturing.

- Sensing: A network of Fiber Bragg Grating (FBG) sensors—fiber optics as thin as a human hair capable of measuring strain and temperature with high precision—was embedded within the composite layers of the wings and fuselage.

- Onboard Processing: A dedicated avionics unit collected data from the FBG sensor network. The software for this unit was developed to meet stringent aviation safety standards like DO-178C, ensuring its reliability for a flight-critical system.

- Data Analysis: During flight and on the ground, strain data was continuously analyzed for anomalies indicative of micro-crack formation or delamination. This data effectively created a “digital twin” of the airframe, tracking its structural health throughout its operational life.

Outcome: The system transformed the maintenance model from a fixed schedule to condition-based monitoring. This significantly reduced the time aircraft spent on the ground for heavy structural checks, directly increasing fleet availability. More importantly, it provided a major leap in safety by enabling early detection of potential structural issues long before they could become critical.

These examples demonstrate a crucial point: a successful industrial IoT solution is never about technology for its own sake. It is about the expert application of sensors, connectivity, and data analysis to solve a specific, high-value business problem and deliver measurable results.

The rapid advancement in sensor technology is a primary driver of this field’s growth. The IoT sensors market, valued at USD 13.24 billion in 2024, is projected to reach USD 103.1 billion by 2032, reflecting a compound annual growth rate of 32.26%. This expansion highlights the critical role of sensors in unlocking new operational efficiencies. You can read more about the key drivers of the IoT sensor market on GlobeNewswire.

IIoT Solution Impact Analysis Across Industries

The principles discussed apply across diverse industrial sectors. While specific challenges and tools vary, the core strategy of using connected sensors and intelligent data analysis to solve critical business problems remains constant. The following table provides a comparative look at how IIoT solutions are delivering tangible outcomes.

| Industry | Problem Scenario | Applied IIoT Solution | Key Business Outcome |

|---|---|---|---|

| Energy & Utilities | Unpredictable failures in remote pipeline pumps lead to costly environmental cleanup and service disruptions. | Vibration and pressure sensors with satellite connectivity feed a predictive analytics platform to forecast pump failures. | 30% reduction in unplanned downtime and a significant decrease in environmental incident risk. |

| Logistics & Warehousing | Inefficient tracking of high-value assets within a large distribution center causes delays and inventory loss. | RTLS (Real-Time Location System) tags on assets and forklifts provide live location data to a centralized management dashboard. | 15% improvement in order fulfillment speed and a 99.5% accuracy rate for asset tracking. |

| Agriculture | Inconsistent soil moisture and nutrient levels across vast fields result in variable crop yields and wasted resources. | A network of in-ground sensors monitors soil conditions, weather, and crop health, controlling an automated irrigation and fertilization system. | 20% increase in crop yield while reducing water consumption by 25%. |

| Robotics | Collaborative robots (cobots) on an assembly line experience wear and tear, but maintenance is reactive, causing line stoppages. | Embedded sensors in cobot joints monitor torque, temperature, and cycle counts, alerting teams to an upcoming need for part replacement. | Near-elimination of downtime from cobot failure and a 40% reduction in spare parts inventory costs. |

The impact of a well-designed IIoT solution is both measurable and significant, transforming operational data into a strategic asset. Success begins with a clear definition of the business problem to be solved.

Securing Your IIoT Ecosystem from Edge to Cloud

In industrial operations, security is not a feature; it is the foundation of system integrity. The convergence of Operational Technology (OT) and Information Technology (IT) in an industrial IoT solution creates an attack surface far more complex and consequential than that of a typical corporate network.

A security breach in this context is not about data loss; it is about physical consequences: damaged machinery, production halts, or severe safety incidents.

The core challenge is that traditional IT security models are insufficient for the unique constraints of OT. Most industrial control systems (ICS) and legacy equipment were designed long before network connectivity was a consideration and lack native defenses against modern cyber threats. Connecting them to a network without a robust, multi-layered security strategy is a critical vulnerability.

A Defense-in-Depth Strategy for IIoT

A resilient security posture requires a layered approach, protecting every component from the individual sensor to the cloud platform. This strategy, often guided by frameworks like the NIST Cybersecurity Framework, ensures that if one layer is compromised, others are in place to detect, contain, and mitigate the threat.

Common failure modes in IIoT security include overlooking the complete data lifecycle. Device spoofing, where an attacker impersonates a legitimate sensor to inject false data, can compromise operational integrity. Man-in-the-middle attacks, which intercept and alter data in transit, could have catastrophic consequences if an attacker gains control of physical processes.

To defend against these threats, vulnerabilities must be addressed at every point in the architecture.

- Device-Level Security: Security must be designed in, not bolted on. This starts at the hardware level with a secure boot process, which ensures that a device only loads authenticated, trusted firmware, preventing the execution of malicious code.

- Network Segmentation: Critical OT assets must be isolated from the broader network. Creating distinct network zones using firewalls and VLANs severely limits an attacker’s lateral movement, containing the impact of a breach.

- Encrypted Communications: All data, both at rest and in transit, must be encrypted. Standard protocols like TLS (Transport Layer Security) for IP networks and DTLS (Datagram Transport Layer Security) for low-power devices are essential to prevent eavesdropping and data tampering.

- Robust Access Management: The principle of least privilege must be enforced. Users and systems should only have access to the specific data and controls required for their function. Multi-factor authentication (MFA) and role-based access control (RBAC) are fundamental controls.

Addressing Firmware and Supply Chain Vulnerabilities

A significant and often-overlooked threat lies in the supply chain. An IIoT device is only as secure as its weakest component, whether a third-party sensor, a communication module, or its firmware.

Vulnerabilities or malware can be embedded in hardware or firmware long before a device reaches your facility. It is critical to rigorously vet suppliers and enforce a secure software development lifecycle (SDLC) for all firmware. For a deeper analysis, review best practices for security in embedded systems, which form the core of IIoT devices.

The objective of IIoT security is not merely to prevent breaches but to ensure operational resilience. The system must be designed to maintain safe and predictable operations during a security event, isolating the impact and enabling rapid recovery.

A defense-in-depth strategy creates a security posture that protects assets, guarantees data integrity, and maintains operational continuity. It transforms security from a compliance burden into a strategic enabler for a reliable and trustworthy industrial IoT solution. For a closer look at securing OT/IT systems in high-stakes environments, the strategies used for cybersecurity services for the Alberta Oil & Gas industry offer relevant insights.

Planning Your Next Steps in IIoT Implementation

Strategy without execution is ineffective. The most common failure mode in Industrial IoT initiatives is attempting to solve too many problems at once, resulting in a sprawling, unfocused project that delivers no demonstrable value.

Successful IIoT deployment follows a clear principle: start small, prove value quickly, and build momentum.

The most effective path forward is a tightly scoped pilot project focused on a single, high-impact business problem, such as the CNC machine downtime use case. This focus simplifies the definition of success and enables the measurement of a tangible return on investment.

Creating a Blueprint for Success

Before procuring hardware or writing code, several foundational steps are critical for de-risking the project and establishing stakeholder alignment. Rushing this stage often leads to costly rework and delays.

A robust implementation plan must include:

- Conducting a Readiness Assessment: Perform an objective analysis of your current infrastructure, internal skill sets, and operational maturity. Identify and address gaps in network capacity, security protocols, or data management capabilities before proceeding.

- Establishing a Cross-Functional Team: An IIoT project is neither purely IT nor OT. Assemble a core team with experts from operations, engineering, IT, and data science to ensure the solution is technically sound and operationally relevant.

- Defining Clear Success Metrics: Vague goals lead to ambiguous results. Define specific, measurable Key Performance Indicators (KPIs) before starting, such as a 10% reduction in unplanned downtime or a 5% improvement in overall asset utilization.

The cardinal rule of successful IIoT deployment is to design for scale from day one, even during a small pilot. Architecting the solution with future growth in mind prevents the need for a complete re-engineering effort when expanding from ten devices to ten thousand.

This means selecting platforms that support open standards, building modular applications, and ensuring the data infrastructure can handle exponential growth. Getting this right early is the difference between a successful, scalable program and a dead-end pilot project.

Navigating the complexities of hardware selection, firmware development, and systems integration is a significant challenge. Sheridan Technologies offers a high-level technical assessment to help you de-risk your IIoT initiative from the start. Our expert guidance ensures your project is built for first-pass success, saving you time and preventing costly missteps. Start your assessment with Sheridan Technologies.