Table of Contents

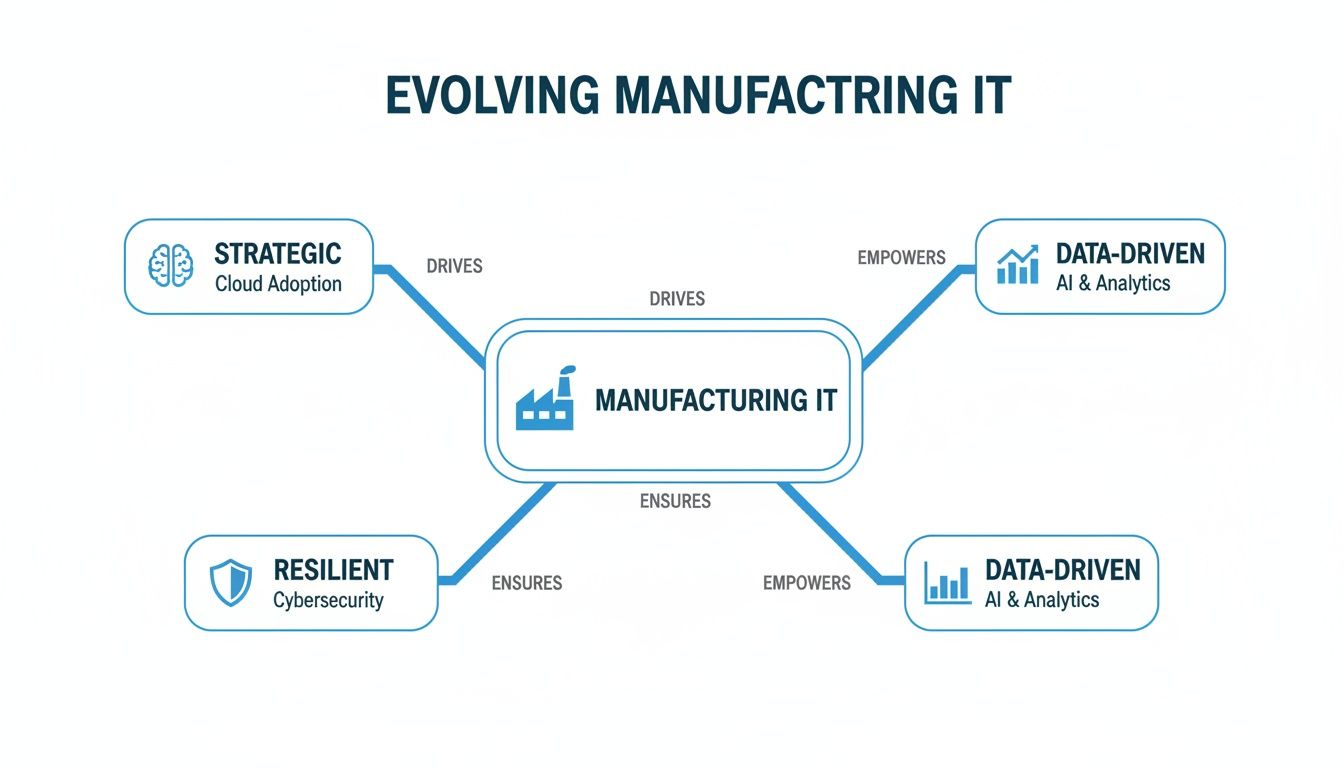

Manufacturing IT services have moved out of the server room and onto the factory floor. They are no longer about keeping office computers running; they’ve become the central nervous system for competitive, resilient manufacturing operations. This is about connecting the machines that make products with the systems that run the business, creating a single, intelligent factory.

Why Manufacturing IT Services Are a Strategic Imperative

Manufacturers today are grappling with a problem decades in the making: operational technology (OT) and information technology (IT) systems that live in separate, siloed worlds. The machines on the shop floor were never designed to talk to enterprise software, and that disconnect is now a major operational and financial liability.

Problem → Diagnosis → Solution → Outcome

Problem: A medical device manufacturer faces unpredictable downtime on a critical CNC machine, leading to missed deadlines and eroding client trust. Their maintenance strategy is purely reactive—a frantic scramble to fix the machine after it has already brought the production line to a halt. This isn’t just inefficient; it’s a massive financial drain, factoring in lost production hours, expedited parts shipping, and emergency labor costs.

Diagnosis: The root cause is a complete lack of data. Legacy setups lead to production bottlenecks, create catastrophic security risks from unpatched machinery, and bury valuable performance data inside isolated equipment. This technological debt directly constrains growth, making it nearly impossible to pivot when supply chains break or customer demands change. Without real-time visibility into the machine’s health, the maintenance team is flying blind.

Solution: The solution isn’t just better IT support; it’s a strategic integration of OT and IT. This means getting systems like SCADA and MES to communicate seamlessly with ERP and cloud analytics platforms. For many, tackling outdated infrastructure with smart legacy system modernization strategies is the critical first step. By deploying targeted IIoT sensors and an analytics platform, the manufacturer can shift from reactive repairs to predictive maintenance, anticipating failures before they occur.

Outcome: The results of this integration are tangible and measurable business impacts:

- Reduced Operational Risk: A unified security approach for both IT and OT, often aligned with standards like IEC 62443, dramatically shrinks the attack surface, protecting intellectual property and preventing costly downtime.

- Accelerated Speed to Market: Real-time production visibility allows for instant identification and resolution of quality issues or bottlenecks, shortening cycle times.

- Enhanced Cost Control: Granular performance data enables predictive maintenance before equipment fails, optimizes energy consumption, and reduces material waste.

The Shift from Tactical IT to Strategic Manufacturing IT

This table breaks down the fundamental change in mindset and its impact on the business.

| Aspect | Traditional Tactical IT (The Problem) | Strategic Manufacturing IT Services (The Solution) | Business Impact |

|---|---|---|---|

| Focus | Keeping office systems online. | Integrating plant floor (OT) with business systems (IT). | Holistic operational visibility from shop floor to top floor. |

| Security | Siloed policies for IT and OT (if any). | Unified, end-to-end cybersecurity posture (e.g., NIST CSF, IEC 62443). | Reduced risk of production downtime from cyberattacks. |

| Data Flow | Data is trapped in individual machines or systems. | Seamless, real-time data flow across the enterprise. | Data-driven decisions, predictive maintenance, and quality control. |

| Role of IT | A reactive, break-fix cost center. | A proactive partner in driving business value. | IT becomes a core driver of efficiency, innovation, and growth. |

The move from a reactive stance to a proactive, strategic one is what separates market leaders from laggards.

Investing in the Future of Production

This isn’t just a theoretical shift; it’s backed by significant investment. According to a 2023 report by MarketsandMarkets, the global smart manufacturing market is projected to reach $589.98 billion by 2028, growing at a CAGR of 13.4%. This spending confirms that leading manufacturers no longer see IT as a simple cost center. It’s a primary engine for creating value. You can explore our own insights on how these investments pay off with effective digital transformation solutions.

A truly strategic manufacturing IT service isn’t about buying more software; it’s about architecting a system where data from a machine tool on the floor can securely and reliably inform a critical business decision in the front office in near real-time.

Embracing modern manufacturing IT services is a core business decision. It’s about building an organization that is nimble enough to navigate disruptions, efficient enough to control costs, and intelligent enough to seize new opportunities. The manufacturers making this pivot today are the ones who will define the next era of industry.

Breaking Down the Core Components of Manufacturing IT

To build a factory that is both resilient and data-driven, you must understand the technology holding it all together. These are not disparate tools; they are interconnected systems that must communicate reliably. Effective systems integration services are essential to ensure these components work in concert to create tangible business value.

OT and IT Convergence: The Foundation of Data Flow

For decades, a hard wall has stood between Operational Technology (OT)—the hardware and software that directly monitors and controls physical devices—and Information Technology (IT). This divide is a primary source of inefficiency. OT systems like PLCs and robots have traditionally been isolated, creating a significant blind spot for the enterprise.

The problem is that critical production data gets trapped on the factory floor, invisible to business systems. You cannot make informed, real-time decisions without a complete operational picture.

The solution is IT/OT convergence, the deliberate strategy of breaking down that wall. It involves creating a single, secure network where data from machines can be collected, contextualized, and shared with IT platforms like an ERP or cloud analytics tools. When executed properly, you create a single source of truth for operational performance.

This model is powered by data analytics and wrapped in a robust layer of security, making it a strategic driver, not just a cost center.

MES and SCADA: Digital Command and Control

If IT/OT convergence builds the data highways, then Manufacturing Execution Systems (MES) and Supervisory Control and Data Acquisition (SCADA) systems are the command center and traffic control.

- SCADA: Provides real-time visibility and control on the plant floor. SCADA systems interface directly with PLCs and sensors to acquire data and issue commands. It is the nervous system of the plant.

- MES: Sits above SCADA, providing context to the data. It answers the “why” behind SCADA’s “what.” An MES manages production schedules, tracks materials, enforces workflows, and creates a complete digital production record (e-DHR).

Tradeoff: SCADA systems prioritize real-time control and availability, often at the expense of security features common in IT. MES integration must be carefully designed to pull data without compromising the low-latency, deterministic performance required for machine control.

IIoT: The Source of Granular Data

The Industrial Internet of Things (IIoT) elevates data collection from basic to high-fidelity. It involves deploying smart sensors and devices on equipment—including legacy “dumb” machines—to capture detailed operational data previously unavailable.

The problem is that you know a machine is running, but you lack data on its precise temperature, subtle vibration signatures, or real-time energy consumption. This data deficit precludes advanced capabilities like predictive maintenance.

The solution is deploying IIoT sensors to create a high-definition data stream. For instance, a high-frequency vibration sensor on a motor can detect the subtle changes that indicate an impending bearing failure, long before it causes a catastrophic line stoppage. A well-designed industrial IoT solution can transform maintenance from a reactive cost center into a proactive, value-driving function.

Cloud, Edge, and Cybersecurity: The Enabling Infrastructure

None of this works without a resilient and secure infrastructure. This is the final, crucial piece of the puzzle.

- Cloud & Edge Computing: These work in tandem. Edge computing processes data at the source—on the factory floor—for low-latency decisions where milliseconds matter (e.g., quality control rejection or safety stops). The cloud provides the massive compute and storage horsepower for complex, long-term analysis, such as training machine learning models across an entire fleet of assets.

- Networking: The network is the circulatory system. It must be segmented, typically following a model like the Purdue Model for ICS, to isolate critical OT systems from the broader IT network. This prevents a security breach in the corporate environment from propagating to the production line.

- Cybersecurity: This is not an add-on; it is a foundational requirement. Cybersecurity in manufacturing must address threats from both IT (phishing, ransomware) and OT (PLC vulnerabilities, protocol-level attacks) with a unified strategy, often guided by standards like NIST CSF or the ISA/IEC 62443 series.

From Theory to Reality: A Predictive Maintenance Use Case

General concepts are insufficient; a real-world use case demonstrates how manufacturing IT services deliver tangible business impact. Let’s walk through a practical scenario, connecting these technologies to a common, costly problem on the factory floor.

Problem: A Critical Production Bottleneck

A medical device manufacturer operates under stringent deadlines and quality standards (e.g., ISO 13485). Their entire operation depends on a multi-axis CNC machine that produces high-precision components. This machine fails frequently and without warning.

Unplanned downtime is the primary business risk. Each failure shreds production schedules, resulting in expensive operator overtime and, more critically, missed delivery dates that damage client trust. The maintenance strategy is purely reactive: fix the machine after it has already stopped production.

Diagnosis: Unpredictable Bearing Wear as Root Cause

An analysis identifies the root cause: premature and unpredictable failure of the bearings in the CNC machine’s primary spindle. The maintenance crew has no way to anticipate these failures. They are trapped in a cycle of reactive repairs, replacing parts only after a breakdown has occurred.

This is a significant financial drain. The cost of each incident far exceeds the cost of a new bearing, encompassing lost production hours, premium-paid expedited parts shipping, and the labor costs of emergency repairs. The fundamental issue is a complete lack of predictive data.

Solution: A Targeted IIoT and Analytics Project

To shift from reactive to proactive maintenance, the company deploys a focused manufacturing IT services project. The goal is to predict bearing failure before it happens, allowing maintenance to be scheduled during planned downtime.

Here is the solution architecture:

- Retrofitting with IIoT Sensors: High-frequency vibration and temperature sensors are mounted near the spindle bearings to capture subtle operational data.

- Edge Data Processing: Raw sensor data is ingested by a local edge gateway. This device performs initial filtering and aggregation at the source, reducing network load and ensuring only relevant data is transmitted for analysis. This is critical for hard real-time vs soft real-time decision-making.

- Secure Cloud Ingestion: The processed data is securely streamed to a cloud platform designed for high-volume time-series data from industrial assets.

- Machine Learning Analysis: In the cloud, a machine learning model analyzes incoming vibration and temperature patterns. The model is trained to recognize the unique digital signatures that precede bearing failure, distinguishing them from the noise of normal operation.

This project is not about collecting data for its own sake. It’s about translating physical signals—like a minute increase in high-frequency vibration—into a clear, actionable business insight: “This specific bearing has a 95% probability of failure within the next 72 hours.”

Outcome: Measurable Business Improvements

The rollout of this predictive maintenance system delivered immediate and significant results. The machine learning model began predicting impending bearing failures with high accuracy, automatically generating work orders in the CMMS for the maintenance and operations teams.

This foresight was a game-changer, allowing the company to schedule repairs during planned shutdowns and transforming its operational posture. The tangible business outcomes included:

- A 40% reduction in unplanned downtime for the critical CNC machine.

- A 25% decrease in overall maintenance costs due to the elimination of emergency repairs and optimized parts inventory.

- Improved on-time delivery metrics, which strengthened customer trust and secured future orders.

By integrating a targeted set of manufacturing IT services—from IIoT sensors on the shop floor to AI in the cloud—the company converted a major operational liability into a competitive advantage, directly improving its bottom line and production reliability.

A Practical Roadmap for Implementing Manufacturing IT

Implementing a comprehensive manufacturing IT strategy can be overwhelming. The key is to approach it as a phased journey, not a single monolithic project. This blueprint ensures each step builds on the last, delivers value, and manages risk, avoiding team burnout and budget overruns.

Phase 1: Assessment and Strategy

Before purchasing any new technology, conduct a thorough assessment of your current state. You cannot chart a course without knowing your starting point. This phase is about gathering intelligence and building a business case grounded in shop-floor reality, not technology hype.

Conduct a deep audit of your current OT and IT infrastructure, mapping every PLC, network switch, server, and software application. Document age, patch levels, and interconnectivity. Concurrently, interview plant managers and line operators to identify their primary pain points: unplanned downtime, quality control issues, or a lack of inventory visibility.

This diagnosis enables you to set clear, measurable goals. Instead of a vague target like “improve efficiency,” aim for a specific objective, such as, “reduce unplanned downtime on Line 3 by 20% within nine months.”

Tradeoff: This discovery phase requires a significant upfront investment of time and resources. However, skipping or rushing it is a major risk. A failure to correctly identify the core problem can lead to a failed project that erodes internal support for future initiatives.

Phase 2: Building the Foundation

With a clear strategy, you can begin laying the technological and procedural groundwork. This phase is about creating a secure, scalable, and well-governed environment. Attempting to deploy advanced analytics on an unstable foundation is a recipe for failure. Security and data integrity must come first.

Key activities include:

- Network Segmentation: This is non-negotiable. Create a strong barrier between your OT and IT environments, typically following a framework like the Purdue Model. This is a critical control to prevent a security breach on the corporate network from shutting down production.

- Data Governance Framework: Establish clear rules for data ownership, access control, and quality assurance. A solid framework ensures that the data used for decision-making is reliable, consistent, and secure.

- High-Value Pilot Project: Do not attempt to overhaul the entire factory at once. Select one high-impact, low-risk project to prove the concept. A predictive maintenance sensor array on a single, critical machine—as detailed earlier—is an ideal example. A successful pilot builds momentum and provides invaluable lessons for a wider rollout.

Phase 3: Integration and Optimization

Once the pilot project demonstrates a clear return on investment, it’s time to scale and deepen system integration. This is where the vision of a connected factory becomes a reality as you break down data silos.

The first major step is often connecting the MES directly to the ERP system. This integration allows real-time production data to automatically inform financial forecasting, inventory management, and supply chain logistics. From there, deploy analytics platforms that pull data from MES, SCADA, and IIoT devices to provide a holistic view of plant performance. Methodically expand the successful pilot project to other production lines or facilities, leveraging lessons learned to accelerate each subsequent deployment.

Phase 4: Unlocking Advanced Capabilities

With a fully integrated, data-rich environment, you can now pursue advanced capabilities that provide a significant competitive advantage. This is where your investment in manufacturing IT services truly pays off, shifting you from operational improvement to genuine innovation. Many of these advanced steps tie directly into broader industrial automation solutions.

This advanced stage enables capabilities such as:

- Predictive Quality and Maintenance: Use AI and machine learning models to predict quality defects before they occur or forecast maintenance needs across the entire equipment fleet.

- Digital Twins: Create dynamic virtual models of production lines or products. These “twins” allow you to simulate process changes, optimize performance, and train operators in a risk-free environment.

- AI-Driven Process Control: Leverage AI to build closed-loop control systems that automatically adjust machine parameters in real-time to optimize for energy consumption, material usage, or output quality.

How to Select the Right Manufacturing IT Service Partner

Choosing a partner for your manufacturing IT services is a critical decision. The right partner acts as a force multiplier, accelerating progress and de-risking the project. The wrong one can lead to budget overruns, stalled projects, and a “solution” that provides no business value.

The goal is to find a team whose expertise mirrors the unique technical and regulatory landscape of your factory floor, not just a generic IT provider.

Differentiating Between IT Generalists and OT Specialists

One of the most common and costly mistakes is assuming that general enterprise IT skills translate directly to a manufacturing environment. They do not. Your partner must demonstrate deep, hands-on experience in both Information Technology (IT) and Operational Technology (OT). They need to be as comfortable with PLCs, SCADA systems, and industrial networking protocols as they are with cloud architecture and cybersecurity.

This dual fluency is non-negotiable. An IT-only provider will likely not grasp the real-time constraints and safety implications of OT systems. Conversely, an OT-only provider may lack the robust cybersecurity and data architecture expertise needed to securely connect the plant to the enterprise.

To vet a potential partner, demand specific case studies where they have successfully bridged the IT/OT divide. Probe their understanding of industrial control system standards, such as ISA/IEC 62443.

Industry-Specific and Regulatory Expertise

Manufacturing is not a monolith. The requirements of an aerospace facility operating under AS9100 are vastly different from a medical device plant governed by FDA regulations and ISO 13485. A partner with direct experience in your specific vertical understands your unique challenges, quality standards, and regulatory burdens from day one.

This specialized knowledge prevents a painful and expensive learning curve. It also ensures that the proposed solution is compliant by design, not as an afterthought. For instance, a partner familiar with medical device manufacturing will understand the data logging and validation requirements for production systems and build them into the project plan from inception.

Verifying Technical and Integration Capabilities

A partner’s skill is revealed in their ability to integrate disparate systems. This is particularly true for IIoT projects, which often involve integrating new sensors with legacy machinery that may be decades old.

A partner’s true value is revealed when they can seamlessly integrate custom firmware on an embedded device, securely stream its data across a segmented network, and connect it to a cloud-based analytics platform. This end-to-end capability is what separates true integrators from mere resellers.

Artificial intelligence has become a powerful tool, and any credible partner should be able to explain precisely how they use it to solve real-world factory problems. For instance, AI-driven applications in manufacturing can reduce defect rates by up to 30% with advanced quality control systems. When IIoT and AI are combined for predictive maintenance, downtime can be cut by 50% and maintenance costs reduced by 40%. You can learn more about AI’s impact on manufacturing efficiency and its growing role.

Flexible Engagement vs. Rigid Contracts

Finally, scrutinize their engagement model. Rigid, old-school contracts rarely accommodate the realities of complex engineering projects where requirements can evolve. A flexible model that allows you to scale expertise up or down is far more effective.

Look for a partner who offers a Dynamic Expert Network. This structure enables them to bring in elite specialists—such as a firmware engineer for one phase or a machine learning expert for another—at the precise moment they are needed, and then rotate them out. This provides best-in-class talent without the overhead of a large, fixed team, ensuring you only pay for the expertise you are actively using. It is an agile approach that keeps projects lean and on schedule.

Taking the Next Step: Your Move to a Data-Driven Factory Floor

Modernizing your plant is a fundamental business decision, not just a technology project. The objective is to move forward with purpose, turning the vast amount of data generated on your factory floor into a competitive advantage. This journey is about delivering three powerful outcomes: reducing risk with unified cybersecurity, accelerating speed-to-market through connected operations, and tightening cost control with data-driven optimizations.

A full rip-and-replace is not the answer. The most successful projects start small. They identify one specific, high-impact pain point and solve it decisively. This approach secures an early win, provides a clear ROI, and builds the momentum needed for broader organizational buy-in.

Start with a Targeted Assessment

Identify your most significant operational risk or cost center. Is it the threat of a cyberattack halting production? Or is it the unpredictable financial drain from equipment failures?

Two of the most effective starting points are:

- A Comprehensive OT Security Audit: This is a deep dive into the vulnerabilities within your plant floor network, control systems, and machinery, aligned to a framework like IEC 62443 or the NIST CSF. The outcome is a clear, prioritized roadmap to mitigate your most immediate cyber risks and build a more resilient manufacturing environment.

- A Predictive Maintenance Feasibility Study: This focuses on a single, critical asset. The study analyzes the business case for using IIoT sensors and analytics to predict failures. It will detail the potential ROI in hard numbers—reduced downtime, lower maintenance costs, and more predictable output.

The core mission is to shift from a reactive, “firefighting” mode to a proactive, predictive one. A targeted assessment provides the hard data required to justify the initial investment and ensures your first step into advanced manufacturing IT services delivers measurable results.

Embarking on this path can feel daunting, but you do not have to go it alone. The right partner can help diagnose the most urgent problems and map a practical course, starting with an initial pilot project and scaling to a fully integrated, data-driven factory.

At Sheridan Technologies, our specialty is bridging the gap between complex operational challenges and clean, engineered solutions. We invite you to have a brief, no-obligation chat with us to discuss your specific goals. Together, we can build an actionable plan for your first high-impact project.

FAQ: Your Top Questions Answered

When upgrading factory floor technology, the critical questions are about maintaining uptime, making smart investments, and securing systems without impeding operations. Here are answers to common questions from plant managers and executives.

How Do We Integrate New Systems Without Disrupting Production?

Downtime is the primary constraint, and a “rip and replace” approach is not a viable option. The solution is a careful, phased strategy that respects your production schedule.

We never test on a live system. The process begins by creating a parallel, sandboxed environment—a “digital twin” of your production line. In this safe environment, we validate every connection between the new MES or IIoT network and your existing equipment, such as PLCs and the company ERP. We ensure data integrity and system interoperability before deployment.

Go-live is executed surgically during a planned maintenance window. Even then, we start by bringing the new system online for a single, non-critical production line first. This pilot line serves as a final, real-world validation, allowing us to resolve any issues in a contained area before a facility-wide rollout. This methodical approach de-risks the project and ensures operational continuity.

What Is a Realistic Budget for a Pilot Project?

Budgeting for manufacturing IT services becomes clearer when focused on solving a specific, high-value problem. A pilot project needs a clear business goal.

A predictive maintenance pilot on a single, critical asset is an excellent starting point. A realistic budget for such a project typically falls in the $50,000 to $150,000 range.

This investment typically covers:

- Deep-Dive Assessment: Analysis of the machine’s specific failure modes and the data required to predict them.

- Hardware: IIoT sensors (vibration, temperature, etc.), an edge gateway for local data processing, and necessary networking gear.

- Software & Cloud Setup: Configuration of data pipelines, cloud storage, and the initial machine learning model trained on your machine’s operational signature.

- Integration & Training: Physical installation, network integration, and training for your maintenance team on interpreting system alerts and data.

The pilot’s goal is to deliver a clear, measurable win—such as a significant reduction in unplanned downtime—that builds the business case for expansion.

How Do We Secure OT Systems Without Hindering Operations?

Securing the plant floor (Operational Technology) is fundamentally different from securing the front office (IT). In OT, the highest priorities are availability and safety. Running a standard IT vulnerability scanner on an OT network could crash a sensitive PLC and halt a production line.

The solution is a defense-in-depth strategy, often guided by a framework like the ISA/IEC 62443 standard. It involves creating multiple security layers that protect critical equipment without interfering with its real-time operational requirements.

Here is how this works in practice:

- Network Segmentation: This is non-negotiable. We implement industrial firewalls to create a functional “air gap” between the corporate IT network and the OT network, following the Purdue Model. A ransomware attack in accounting should have zero technical path to your machinery.

- Industrial Intrusion Detection (IDS): These tools passively monitor OT network traffic for anomalous behavior, understanding industrial protocols like Modbus or PROFINET. They can detect threats without actively probing and potentially disrupting sensitive control systems.

- Controlled Patching: Security updates are critical but must not compromise stability. We help establish a controlled process where patches are tested in an offline environment first and then deployed during scheduled downtime, ensuring a security fix does not cause an operational failure.

At Sheridan Technologies, our expertise lies in engineering robust, practical solutions that connect your operational goals with the right technology. If you’re ready to build a concrete action plan, schedule a brief, no-obligation consultation to identify your highest-impact starting point.