For small business decision-makers, AI automation is not a speculative future trend; it is a present-day tool for cost control, risk reduction, and operational scaling. The strategic objective is not merely task management, but building a more resilient, scalable enterprise. This is achieved by identifying and replacing high-friction workflows—such as manual data entry or inconsistent customer service protocols—with intelligent, automated systems. The primary business impact is enabling revenue growth that is decoupled from linear increases in payroll.

Moving Beyond Hype to Practical AI Implementation

This guide is engineered to provide actionable intelligence for operators. We will analyze AI automation for small business as a set of deployable tools, not abstract technology. The focus is on accelerating speed-to-market, tightening control over operational expenditures, and mitigating risks associated with manual processes. For a technically literate, time-constrained leader, the value of AI is not in the technology itself, but in its capacity to solve persistent operational problems.

Most small and mid-sized businesses encounter predictable operational drags that constrain growth. These are not minor inconveniences; they are material threats to scalability and profitability.

Diagnosing Common Operational Drags

Effective solutions require accurate diagnosis. Several common symptoms indicate a high-potential opportunity for AI automation:

- Manual Workflow Bottlenecks: Repetitive tasks such as invoice processing, data validation, or manual report generation consume significant labor hours. These processes are not only slow but are also primary sources of human error, introducing financial and operational risk.

- Disconnected Data Systems: When customer, sales, and inventory data reside in disparate, non-integrated systems (e.g., CRM, ERP, spreadsheets), it is impossible to generate a holistic operational view. This data fragmentation leads to suboptimal, reactive decision-making.

- Linear Scaling Dependencies: If the only viable path to revenue growth involves a proportional increase in administrative headcount, core business processes are fundamentally inefficient. This model is unsustainable and caps scalable growth.

When implemented strategically, AI aligns directly with core business objectives. Integrating AI into potent growth strategies for small businesses can streamline operations and enhance customer engagement.

The strategic intent of AI automation is not workforce replacement but workforce augmentation. It addresses low-value, high-volume tasks, thereby liberating skilled personnel to focus on high-impact activities such as product innovation or complex client relationship management.

The Strategic Value of Targeted Automation

This is where targeted AI automation delivers measurable impact. It directly addresses the diagnosed drags by creating more reliable, consistent, and efficient systems. Instead of a monolithic "AI" implementation, consider a portfolio of specific solutions engineered for specific, measurable outcomes.

For example, an AI-powered OCR tool can parse, digitize, and categorize invoices, potentially reducing processing time by over 90%. An intelligent chatbot can be deployed to handle 80% of routine customer inquiries, allowing human support agents to concentrate on complex, high-value escalations. Our guide on digital transformation solutions details the architecture of such systems.

This problem → diagnosis → solution → outcome framework is critical for successful implementation. The following sections provide a clear roadmap for identifying opportunities, executing pilot programs, and measuring tangible return on investment.

Identifying Where to Deploy AI for Maximum Impact

Before evaluating specific tools, the critical first step is a rigorous internal diagnostic. This self-assessment identifies where ai automation for small business will generate a material impact on the bottom line. The goal is to pinpoint sources of operational friction—repetitive tasks, data-intensive processes, and error-prone workflows—rather than pursuing technology for its own sake.

A structured analysis of core business functions is the most direct path to a high-value pilot project. This begins with workflow mapping to identify bottlenecks. This strategic shift is widespread; a 2023 survey revealed that 57% of U.S. small businesses are actively investing in AI. It has transitioned from a niche technology to essential infrastructure, with 55% integrating it into product development and 54% leveraging it to fortify operations and supply chains.

Analyzing Your Operations

Day-to-day operations are often the most fertile ground for initial automation wins due to the direct measurability of outcomes. Target processes characterized by high volume, high repetition, and well-defined rules.

- Financial Processes: Manual invoice entry, expense report validation, and accounts payable reconciliation are prime candidates for AI-driven optical character recognition (OCR) and automated approval workflows. These tasks are time-consuming and introduce significant error risk.

- Supply Chain and Inventory: Inaccurate demand forecasting leads to stockouts (lost revenue) or overstocking (increased carrying costs). AI models can analyze historical sales data, seasonality, and market trends to optimize inventory levels, directly impacting cash flow.

- Data Entry and Migration: Manual data transfer between systems like a CRM and an ERP is not just a labor cost; it is a primary vector for data integrity failures, which can lead to costly downstream errors in fulfillment, billing, and reporting.

Evaluating Engineering and Product Development

For businesses developing hardware or software, AI can significantly accelerate innovation cycles and improve quality control. The strategy is to automate the non-creative, repetitive aspects of the engineering workflow.

Consider an AI system that automates firmware regression testing overnight. Engineers arrive to a concise report of anomalies requiring investigation, a process that can reduce development timelines by weeks. Another high-impact application is using AI agents to scrape supplier databases for component availability and pricing, converting a multi-day manual task into a real-time query. Our analysis of AI solutions for small business provides more technical examples.

Assessing Customer Engagement Points

Customer interactions represent another high-potential domain for automation. The goal is to improve responsiveness and consistency without losing the human element for high-value interactions.

The objective is not to replace human interaction but to augment it. AI should handle the predictable, high-volume queries, freeing up your expert staff to manage complex, high-value customer relationships that truly drive loyalty and growth.

Begin by analyzing support ticket data. If 80% of inquiries pertain to a small set of common issues (e.g., order status, password resets), an AI-powered chatbot or intelligent knowledge base can provide instant resolution. This improves customer satisfaction with 24/7 availability and reduces the load on the support team, allowing them to focus on substantive problem-solving.

A Practical Roadmap for AI Implementation

Integrating AI automation is not a monolithic project but a series of calculated, phased deployments. For operators managing risk and resources, this structured approach is essential for proving value and ensuring controlled execution. This four-phase roadmap guides a project from a narrow, high-impact proof of concept to a fully integrated, scalable solution.

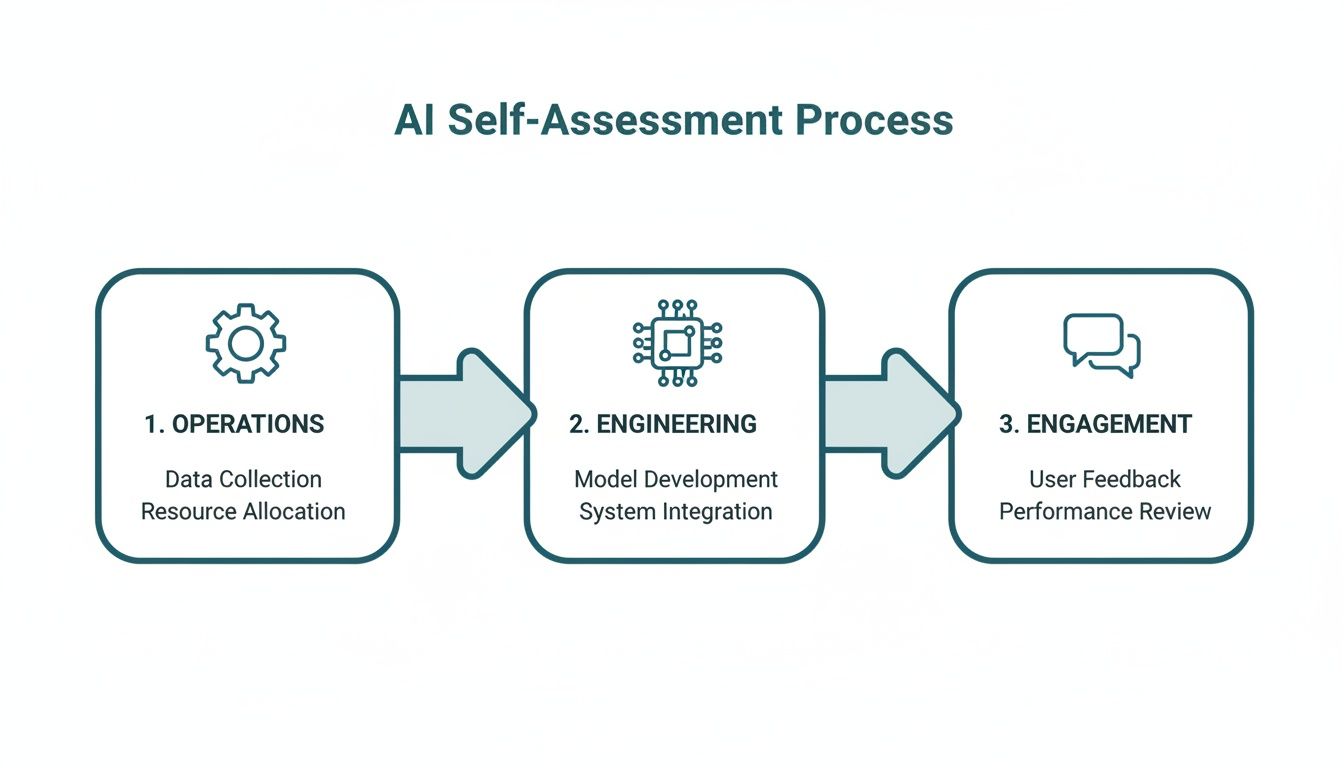

This visual flow breaks down the core areas you'll need to evaluate as you get started.

Successful implementation connects operational data and resources with engineering capabilities, closing the loop with feedback from end-users.

Phase 1: Assessment and Scoping

This initial diagnostic phase is the most critical. The objective is to identify a single, narrow, high-impact problem where AI can deliver a clear, measurable win. Rushing this stage is a common failure mode that leads to projects misaligned with business value.

Your primary goal is to build a data-driven business case. This requires identifying a specific workflow bottleneck and quantifying its current impact. For example, when targeting manual invoice processing, you must establish baseline metrics before implementing automation.

- Key Action: Pinpoint a single, rule-based, high-volume process that is a known source of operational drag.

- Success Criteria: A precise problem statement with baseline metrics. Example: "Reduce average invoice processing time from 4 days to under 8 hours" or "Decrease data entry error rate in order fulfillment from 3% to less than 0.5%."

- Pitfall to Avoid: Avoid "boil the ocean" projects. Attempting to automate an entire department or a complex, multi-stage process from the outset is a recipe for failure. The initial scope must be ruthlessly narrow.

Phase 2: The Pilot Project

With a clear scope, the next step is a small-scale pilot. This is a controlled experiment designed to validate the solution's technical feasibility and business value with minimal investment. The pilot must be isolated enough to avoid disrupting core operations but realistic enough to generate meaningful performance data.

A strong pilot candidate is automating the classification and data extraction from purchase orders from a single supplier. The AI model's speed and accuracy can then be directly benchmarked against the existing manual process.

A successful pilot project is the single most powerful tool for securing broader stakeholder buy-in. It transforms a theoretical discussion about AI's potential into a tangible demonstration of reduced costs, saved time, or improved accuracy.

Phase 3: Integration and Refinement

Once the pilot demonstrates value, the third phase focuses on technical integration and team adoption. The AI solution graduates from a standalone test to an embedded component of daily operations. This involves connecting the AI tool to existing systems (e.g., ERP, CRM) via APIs.

This phase is as much about people as technology. It requires clear communication, hands-on training, and a robust feedback loop for team members interacting with the new workflow. Their input is critical for refining the system and addressing edge cases missed during the pilot.

- Constraint: Data quality is a hard dependency. If the data fed into the AI from existing systems is unstructured or inaccurate, the automation will fail. The "garbage in, garbage out" principle is absolute.

- Success Criteria: The AI solution is successfully integrated with at least one primary business system, and the relevant team is trained and actively using it. Performance is tracked against the baseline metrics established in Phase 1.

Phase 4: Scaling and Optimization

The final phase involves expanding the proven solution across the organization and establishing a culture of continuous improvement. If the pilot automated invoice processing for one department, scaling means rolling it out to all relevant departments. This requires robust infrastructure and a plan for ongoing monitoring and optimization.

AI models are not "set it and forget it" systems. They can experience "performance drift" as business processes or data patterns evolve. A continuous improvement loop—periodically reviewing performance metrics and retraining or fine-tuning the model—is essential for sustained, long-term success. The goal is to create a scalable framework for future ai automation for small business initiatives.

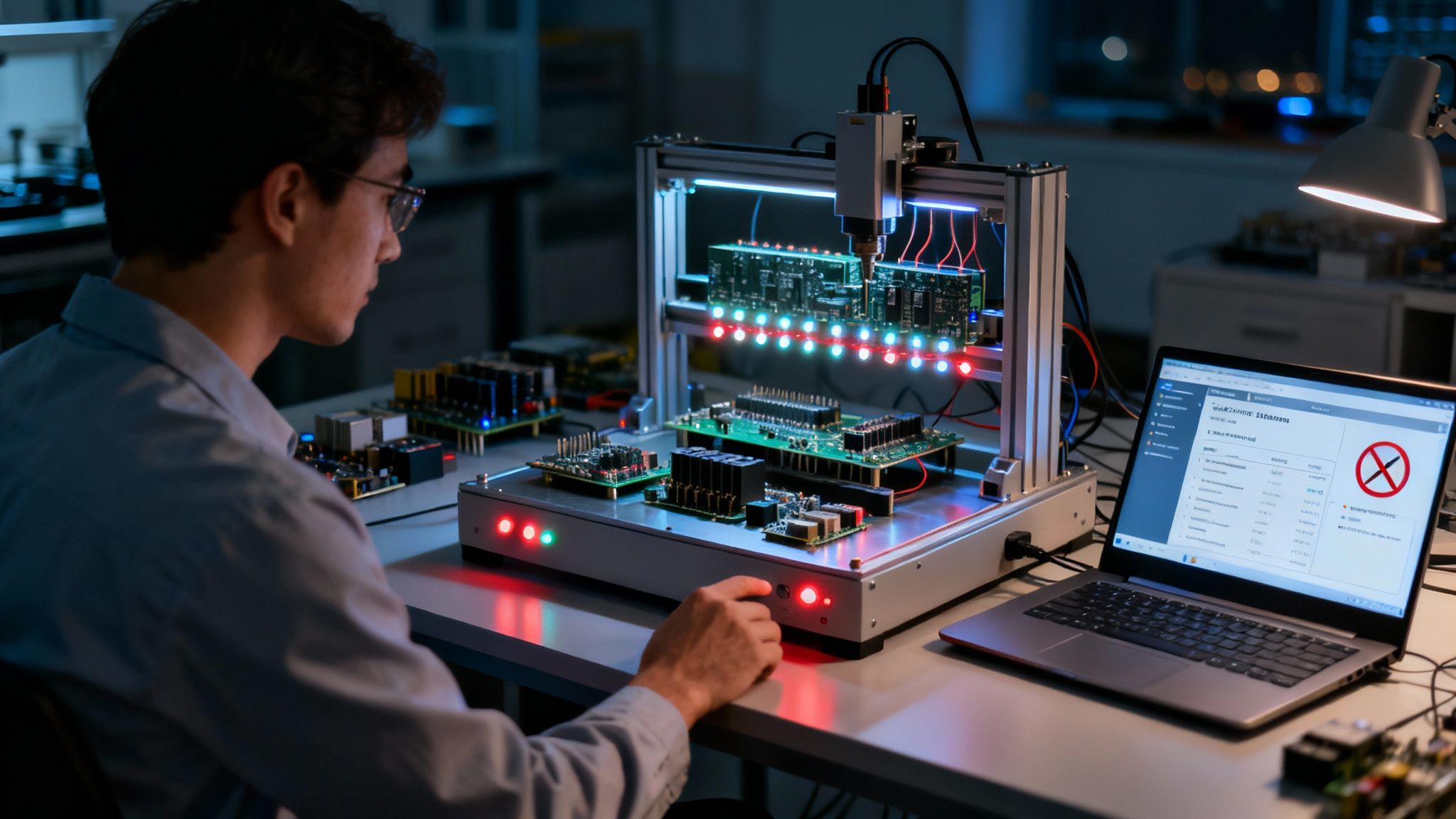

Use Case: Automating a Hardware Prototyping Workflow

To demonstrate AI automation for small business in practice, this section details a real-world scenario for a hardware product team, applying the structured problem-solving framework to address a high-cost operational bottleneck.

Problem: The Prototyping Bottleneck

A small engineering firm developing a new IoT device is constrained by a slow prototype iteration cycle, leading to missed deadlines and budget overruns. The engineering team is overextended, spending a significant portion of their time on repetitive, low-impact tasks. This operational drag directly impacts speed-to-market and consumes cash reserves, creating a critical business risk as competitors gain ground.

Diagnosis: Identifying the Core Constraints

A workflow analysis reveals two specific bottlenecks creating cascading delays. These manual processes are slow and prone to human error.

- Manual Firmware Testing: Following each firmware modification, a junior engineer executes a lengthy regression test suite manually. This process consumes approximately six hours, limiting the team to one or two test cycles per day and diverting engineering talent from core development work.

- Manual Component Sourcing: The procurement manager spends days navigating supplier websites and email chains to confirm component pricing and availability. This creates significant project delays, particularly when a critical component is unexpectedly out of stock, forcing costly, last-minute design revisions.

Both issues are classic examples of operational friction: rule-based, repetitive work that is essential but highly inefficient when performed manually.

Solution: Deploying Targeted AI Agents

Rather than a complete process overhaul, the firm deploys two specific AI-powered automations to address these bottlenecks directly.

First, an automated test harness integrated with an AI anomaly detection model is implemented. Now, every firmware code commit automatically triggers the full regression test suite on the prototype hardware overnight. The AI model analyzes the results, flags any statistically significant deviations from baseline performance, and generates a concise report for engineering review each morning.

Second, an AI procurement agent is deployed. This software agent is configured to scrape a predefined list of approved supplier databases in near real-time. It continuously monitors stock levels and pricing for every component on the project's bill of materials (BOM), issuing alerts when a component's price changes or its stock falls below a predefined threshold.

This is workforce augmentation, not replacement. High-volume, low-cognition tasks are delegated to machines, freeing human experts to focus entirely on analysis, strategy, and complex problem-solving.

Outcome: Measurable Business Impact

The results are immediate and quantifiable. The prototype-to-test cycle time is reduced by over 80%, from a 24-hour manual process to a fully automated overnight run. This enables the engineering team to test multiple iterations daily, dramatically accelerating bug fixes and feature development.

Simultaneously, the AI procurement agent eliminates sourcing delays and provides data for more strategic purchasing, reducing component costs by an average of 12%. This translates directly to budget savings and a faster path to market. This use case is not an outlier; it reflects a broader trend, with some analysts predicting that 75% of small businesses will make significant AI investments by 2027. A large-scale analogue is Ramp's AI system, which processes 400,000 invoices per month with 90% accuracy, saving an estimated 30,000 manual hours annually. More details on this trend are available in these 2026 AI predictions for small businesses.

How to Measure the Business Impact of AI

Deploying AI automation without a clear measurement framework is a strategic failure. To justify the investment and ensure alignment with business goals, operators must move beyond qualitative assessments and establish a robust process for tracking performance against predefined metrics.

The critical discipline is to define specific, measurable KPIs before project initiation. This establishes a clear baseline, making the before-and-after comparison objective and undeniable.

This is not merely about calculating ROI; it's about understanding how specific operational improvements translate into material gains across financial returns, efficiency, and risk reduction.

Financial and Efficiency Metrics

The most direct and compelling metrics are tied to time and money. These KPIs answer the primary stakeholder question: "How is this investment making the business more profitable?"

Begin by calculating the fully-loaded cost of the manual process slated for automation. This includes not only direct labor but also overhead and the cost of error correction.

- Reduced Operational Costs: Quantify direct savings from task automation. If an AI system processes 500 invoices per month, saving 10 minutes each, at a loaded labor rate of $50/hour, the direct savings exceed $4,100 per month.

- Decreased Cycle Times: Measure the end-to-end process time before and after automation. For a hardware team, reducing a firmware test cycle from 24 hours to 4 hours is a significant accelerator for time-to-market.

- Increased Throughput: Track the volume of work completed. An AI-powered customer service bot might handle 300% more initial inquiries during peak hours than a human agent, freeing up personnel for higher-level support.

According to recent Forbes Advisor data, 60% of small business owners view AI as a primary tool for boosting productivity. Some analyses predict employee productivity gains could reach 40%, with reports of companies achieving 23% efficiency gains and recovering an average of 5.6 hours per employee per month. You can review more data on these AI-driven productivity trends for context.

Quality Improvements and Risk Reduction

Some of the most significant benefits of AI deliver long-term strategic value that can be more difficult to quantify in immediate dollar terms. Improvements in quality and risk mitigation strengthen the business and protect the brand.

An effective AI implementation does not just accelerate processes; it makes them more reliable. By systematically reducing the potential for human error, you build a more robust, predictable, and scalable operation.

Focus on these key metrics to track improvements:

- Lower Error Rates: Measure the frequency of errors in data entry, order fulfillment, or financial reporting. Reducing an error rate from 2% to 0.1% eliminates rework costs and improves customer satisfaction.

- Improved Compliance Adherence: In regulated industries, AI can automate the documentation and reporting required by frameworks like ISO 13485 (medical devices), significantly reducing the risk of non-compliance and costly audit failures.

- Enhanced System Uptime: In manufacturing, AI-driven predictive maintenance can identify equipment likely to fail before a breakdown occurs, preventing unplanned downtime and associated production losses.

A clear framework is needed to connect AI activities to business-level KPIs.

Mapping AI Automation to Key Performance Indicators

The following table provides a model for linking specific AI applications to relevant KPIs, ensuring every initiative is tied to a measurable business outcome.

| AI Application | Primary KPI | Secondary Metrics | Business Outcome |

|---|---|---|---|

| AI-Powered Customer Support Bot | First Contact Resolution Rate | Avg. Handle Time, Customer Satisfaction Score (CSAT) | Higher customer satisfaction and reduced support overhead. |

| Automated Invoice Processing | Cost Per Invoice Processed | Cycle Time, Error Rate, On-Time Payment Percentage | Lower operational costs and improved cash flow management. |

| Predictive Maintenance for Hardware | Equipment Uptime Percentage | Mean Time Between Failures (MTBF), Maintenance Costs | Increased production output and reduced capital expenditures. |

| Automated Code Review Assistant | Code Defect Density | Code Review Time, Number of Production Bugs | Faster development cycles and higher software quality. |

| AI-Driven Sales Lead Scoring | Lead-to-Opportunity Conversion Rate | Sales Team Efficiency, Customer Acquisition Cost (CAC) | Increased sales revenue and improved marketing ROI. |

By adopting this metrics-driven approach, you shift from simply implementing technology to strategically engineering business improvements. This discipline is essential for proving the value of AI and building momentum for future initiatives.

Navigating Inevitable Pitfalls and Integration Challenges

Integrating AI automation is a strategic initiative that requires a rigorous assessment of potential failure modes. Many AI projects fail not because of the technology, but due to a handful of predictable and avoidable challenges. Proactively managing these risks is what distinguishes a high-value implementation from one that creates technical debt and operational drag.

The Foundational Challenge of Data Quality

The principle of "garbage in, garbage out" is amplified with AI. An automation model's performance is strictly limited by the quality of its training data. Feeding a model with incomplete, inconsistent, or inaccurate data from legacy systems guarantees unreliable outputs and flawed automated decisions.

A thorough data audit is a non-negotiable prerequisite to implementation. This involves:

- Data Cleansing: Systematically identifying and correcting errors, duplicate records, and inconsistencies within existing datasets.

- Establishing Governance: Implementing clear protocols for data collection, storage, and management to maintain data integrity moving forward.

- Defining Structure: Ensuring data is consistently formatted and labeled, which is critical for the model's ability to interpret information correctly.

Vendor Lock-in and Technical Debt

Selecting an AI vendor is a long-term commitment. A common error is adopting a proprietary, closed-ecosystem platform that appears easy to deploy initially. These systems can create significant technical debt, making it difficult and cost-prohibitive to migrate to a different provider or integrate with other tools in the future.

When vetting vendors, prioritize open standards and comprehensive API documentation. The ability to export your data and integrate with other systems is a critical strategic asset, not an optional feature.

To mitigate this risk, conduct thorough due diligence. Scrutinize data portability policies, API access, and the total cost of ownership, not just the initial licensing fee. Ensure the vendor's product roadmap aligns with your own strategic goals for the next three to five years. This foresight prevents you from becoming captive to a technology ecosystem that constrains future growth.

The Minefield of Security and Regulatory Compliance

Integrating a third-party AI model into your workflow introduces new security and compliance vectors, particularly when handling sensitive customer or proprietary data. You must have absolute clarity on how a vendor handles data, where it is stored, and what security protocols are in place.

For companies in regulated industries such as medical devices (ISO 13485) or aerospace (DO-178C), this is a critical gate. You are ultimately responsible for ensuring any third-party solution meets the stringent documentation, validation, and security requirements mandated by the relevant standards. A compliance failure is not a technical issue; it is a significant business risk that can result in severe financial penalties and reputational damage.

Knowing When to Engage an External Partner

A critical strategic decision is whether to build an AI solution in-house or partner with an external expert. A DIY approach using off-the-shelf software can be effective for simple, well-defined problems. However, the complexity increases substantially for projects involving custom integrations, specialized hardware, or unique business workflows.

In these scenarios, an external partner functions as a strategic accelerator, not just a vendor. Recognizing the signals to engage an expert is crucial for project success.

Key Triggers for Engaging an External Partner

Certain conditions strongly indicate that a project will yield a higher ROI with specialized outside expertise. If these scenarios apply, the cost of a partnership is typically far less than the cost of internal trial-and-error.

- You Lack Specialized AI/ML Talent. Your team may have strong software or hardware engineering capabilities but lacks deep expertise in machine learning, model training, or data science. A consultant provides this specialized knowledge immediately, eliminating a long and costly internal learning curve.

- The Project Requires Complex Hardware/Software Integration. When success depends on blending disparate disciplines—such as firmware development, custom PCB design, and cloud-based AI models—an experienced partner can manage the entire technology stack. This provides a single point of accountability, preventing the integration failures that often derail projects split across siloed teams.

- Speed-to-Market Is the Primary Business Driver. If competitive advantage depends on rapid deployment, a consultant brings focused resources and proven methodologies to meet aggressive deadlines. They are not constrained by your internal resource allocations or organizational processes and can execute without distraction.

The right partner doesn't just build a solution; they de-risk the entire process. They have direct experience with common failure modes—from poor data governance to vendor lock-in—and can navigate these obstacles to ensure a successful deployment.

For any organization facing a gap between internal capabilities and project requirements, exploring a partnership is a logical next step. You can learn more about how these engagements are structured by reviewing our approach to AI consulting services. A focused consultant provides the technical depth and strategic oversight required to transform an ambitious concept into a deployed, value-generating business asset.

If your team is addressing a complex integration challenge or needs to accelerate the path from concept to a scalable AI solution, a brief, confidential assessment with the engineering leads at Sheridan Technologies can provide a clear path forward. Find out more at https://sheridantech.io.