Engineering design services exist to solve one problem: transforming a complex product concept into a market-ready, commercially viable reality. This is a strategic engagement where a company leverages a specialized firm to manage the entire design and development lifecycle—from hardware and firmware to mechanical and systems engineering. The objective is to accelerate speed-to-market, mitigate development risk, and achieve cost predictability by deploying focused, multi-disciplinary expertise.

Why Engineering Design Services Are a Strategic Imperative

The scenario is common: an ambitious product vision is constrained by tight deadlines, fixed budgets, and an already over-extended in-house engineering team. The technical path from concept to production is fraught with risks. Early design flaws trigger expensive rework cycles, while unaddressed manufacturability issues can derail a launch entirely.

Attempting to manage disparate engineering disciplines—firmware, hardware, mechanical, and software—often results in integration failures and communication breakdowns. When these teams operate in silos, projects stall, burn through capital, and miss critical market windows.

A Coordinated Approach to De-Risk Development

An end-to-end engineering services partner functions as the general contractor for a high-tech product. Just as you wouldn't hire an electrician, plumber, and structural engineer for a skyscraper and simply hope they coordinate, an engineering firm orchestrates the specialized disciplines to ensure they work as a cohesive, integrated system.

This integrated approach delivers direct business impact:

- Risk Reduction: An experienced partner identifies potential failure modes early. They apply critical methodologies like Design for Manufacturability (DFM) and Design for Assembly (DFA) from day one, not as a late-stage checklist item.

- Speed to Market: On-demand access to a vetted network of specialists allows teams to scale and deploy specific expertise in days, not the months required for traditional hiring cycles.

- Cost Control: This model avoids the significant overhead of maintaining a full-time, multi-disciplinary engineering staff. Capital is deployed only for the specific expertise needed at each project stage.

The core value of engineering design services is converting technical uncertainty into a predictable, managed process. This provides the strategic capability to pursue ambitious product goals without being derailed by operational drag.

The global engineering services market reflects this reality. Valued at USD 2.34 trillion in 2025, it is projected to reach USD 5.37 trillion by 2034. This growth underscores the essential role these firms play in tackling complexity across industries like medical devices, robotics, and aerospace. The Asia Pacific region leads this trend, holding a 37.30% market share in 2025, driven by Industry 4.0 adoption and significant investments in AI-driven automation. Further market analysis is available from Fortune Business Insights.

The Core Disciplines That Drive Product Success

A successful product is not the result of a single discipline but the integration of multiple engineering functions operating in concert. Beyond initial concepts, a product's commercial viability depends on tactical execution within each core engineering domain.

A common failure mode is a siloed development approach. When teams are not tightly integrated, the result is designs that are difficult to manufacture, unreliable in the field, or too costly to produce. The primary challenge for any project leader is ensuring constant communication between domains. A seemingly minor hardware decision can create significant downstream challenges for the firmware team or compromise the mechanical enclosure's thermal performance.

Hardware and Firmware Engineering

At the core of any electronic device are two inseparable elements: the hardware—the physical printed circuit board (PCB) and its components—and the firmware, the low-level software that controls it. This is where a product's fundamental functionality and reliability are established.

Problem → Diagnosis → Solution → Outcome

- Problem: A medical diagnostics company is developing a portable analysis device. The prototype produces inconsistent sensor readings and experiences frequent crashes, jeopardizing their clinical trial timeline and path to ISO 13485 certification.

- Diagnosis: A post-mortem reveals a classic hardware/firmware disconnect. The hardware team selected an Analog-to-Digital Converter (ADC) with insufficient precision. Concurrently, the firmware team implemented blocking code that prevented the real-time operating system (RTOS) from servicing critical sensor data deterministically.

- Solution: A competent engineering partner addresses this holistically. They perform a signal integrity analysis and specify a new ADC with the required bit depth and sampling rate. Simultaneously, the firmware is re-architected to use non-blocking drivers and a proper task prioritization scheme within the RTOS, ensuring the hard real-time performance the device requires.

- Outcome: The redesigned system delivers stable, accurate readings, enabling the company to proceed with clinical trials on schedule and maintain its certification timeline. The business impact is a direct reduction in regulatory risk and a faster path to revenue.

Mechanical and Systems Engineering

Mechanical engineering defines the physical reality of a product—its enclosure, thermal management, and durability. Systems engineering ensures that all individual subsystems, from the PCB to the user interface, function as a single, cohesive unit that meets top-level requirements.

This is also where long-term reliability and unit production cost are controlled. In many sectors, supporting infrastructure like high-quality Laboratory Design is critical for innovation, directly influencing the environments where new products are developed and validated.

One of the most critical and frequent mistakes is deferring Design for Assembly (DFA) analysis until late in the development cycle. An electronically elegant design is commercially worthless if it cannot be manufactured efficiently and reliably at scale. This oversight leads to inflated labor costs and unacceptable production defect rates.

Engineering Disciplines and Their Strategic Deliverables

This table breaks down the core services, their primary functions, key deliverables, and critical integration points.

| Discipline | Primary Function & Problem Solved | Key Deliverables | Critical Integration Point |

|---|---|---|---|

| Firmware Engineering | Writing low-level code that directly controls hardware. Solves issues like device initialization, real-time control, and power management. | Bootloaders, RTOS configurations, device drivers, board support packages (BSPs). | Hardware design choices dictate firmware complexity and driver requirements. |

| Hardware Engineering | Designing PCBs and selecting components. Solves signal integrity, power distribution, and component lifecycle challenges. | Schematics, PCB layout files, Bill of Materials (BOM), fabrication & assembly drawings. | Mechanical enclosure design for thermal dissipation and physical component fit. |

| Mechanical Engineering | Designing enclosures and structural components. Solves thermal management, durability, and manufacturability problems. | 3D CAD models, FEA/CFD simulation reports, Design for Assembly (DFA) analysis. | PCB form factor and connector placement defined by hardware engineering. |

| Systems Engineering | Ensuring all disciplines work together to meet top-level requirements. Solves integration failures and requirement gaps. | System architecture documents, requirements traceability matrix, test plans. | The central hub connecting all other disciplines to the project's business goals. |

Viewing these as interconnected functions, rather than discrete services, is essential for transforming a high-risk concept into a reliable, manufacturable, and profitable product.

Choosing the Right Project Engagement Model

Selecting an engineering design partner is only the first step. Structuring the engagement model is equally critical to achieving the desired outcome. The engagement model defines risk allocation, budget predictability, and the ability to adapt to development challenges. The wrong model can create friction, misalign incentives, and jeopardize the entire project.

Three primary models exist, each with specific trade-offs. The correct choice is almost always determined by the project's maturity: is it in an early, exploratory R&D stage, or is there a well-defined plan ready for execution?

Time & Materials (T&M) vs. Fixed Price

A Time & Materials (T&M) model is best suited for projects with significant unknowns. It is ideal for early-stage development, R&D, or project rescue scenarios. You pay for the hours worked and materials consumed, providing maximum flexibility to pivot as technical hurdles emerge and requirements evolve. The primary risk is uncontrolled scope creep, which requires disciplined project management to mitigate.

Conversely, a Fixed Price model offers budget predictability. This approach is effective when requirements are well-defined, documented, and stable. The design firm assumes the risk of cost overruns but typically includes a risk premium in the quote. The main drawback is rigidity; any change requires a formal change order, which can slow momentum.

For more on initial scoping, see our guide on the discovery phase of a project.

A hybrid approach is often optimal. A project can begin with a T&M model for the initial discovery and prototyping phases, allowing for rapid iteration and technical de-risking. Once the design is validated and requirements are locked, the engagement can transition to a Fixed Price agreement for final execution and transfer to manufacturing.

Dedicated Team and Retainers

For long-term, complex product development, a Dedicated Team or Retainer model is often the most effective. This embeds a team of specialists who function as an extension of your in-house staff, building deep product and institutional knowledge. This ensures consistent, guaranteed access to critical resources. The trade-off is a committed monthly cost, making it less suitable for smaller, short-term projects with a narrow scope.

Real-World Application: Robotics Startup

- Problem: A startup is building a novel warehouse automation robot. The core mechatronics and control systems are unproven, requiring significant R&D.

- Diagnosis: The scope is ill-defined, making a Fixed Price quote impossible to generate accurately. A rigid contract would penalize the very experimentation required for success.

- Solution: They engage an engineering services firm on a T&M model for the initial three-month proof-of-concept phase. This allows the joint team to test different sensor technologies and iterate on the mechanical design without administrative friction.

- Outcome: After successfully building a functional prototype, the path to a production-ready version is clear. With a well-defined scope, they transition to a Fixed Price contract to build 10 pre-production units, achieving budget predictability for the execution phase. The engagement model was correctly matched to the project's stage of maturity.

Navigating High-Stakes and Regulated Industries

In medical, aerospace, and industrial automation, compliance is not a feature; it is the foundation. A failure is not a bug but a critical safety event with severe real-world consequences. In these domains, engineering design services must function as a risk mitigation partner, not just an execution vendor.

Projects in these sectors are governed by stringent, non-negotiable standards. Every design decision must be deliberate, meticulously documented, and auditable. This reality fundamentally alters the engineering process.

Integrating Compliance from Day One

The most costly mistake is treating regulatory compliance as a post-development activity. Attempting to retroactively create documentation or redesign for safety is a recipe for catastrophic budget overruns and crippling delays.

Effective engineering design services integrate these frameworks from the initial concept. Every decision—from component selection to firmware architecture—is made through the lens of compliance.

- Medical Devices: Development must adhere to the quality management systems of ISO 13485. This requires maintaining a rigorous Design History File (DHF) that traces every requirement, decision, and verification activity.

- Aerospace & Avionics: Flight-critical software is governed by DO-178C, which demands a level of process rigor and traceability to ensure deterministic, fail-safe performance.

- Industrial Automation: In environments with human-machine interaction, standards like ISO 13849 define requirements for safety-related control systems.

A classic failure mode is selecting a microcontroller early in the design without fully vetting its safety certification status or the availability of a certified real-time operating system (RTOS). This single oversight can force a complete hardware and firmware redesign late in the project, costing hundreds of thousands of dollars and months of delay.

For a deeper dive into these requirements, see our guide on medical device development services.

A Real-World Failure and Recovery Scenario

Problem: An industrial automation company developed a new controller for a robotic arm. During pre-certification testing, the emergency-stop function exhibited an unacceptable delay—a critical failure under safety regulations.

Diagnosis: The firmware was not designed with hard real-time constraints. The main control loop was intermittently blocked by lower-priority tasks like data logging, creating an unpredictable and unsafe system. The original team had not conducted a formal Failure Mode and Effects Analysis (FMEA), which would have identified this risk early.

Solution: An expert engineering team was brought in to re-architect the firmware. They implemented a pre-emptive RTOS, assigned the highest priority to the safety monitoring task, and isolated it from non-critical functions. They also conducted a thorough FMEA to identify and mitigate other potential failure modes.

Outcome: The redesigned controller passed certification. The company avoided a costly product recall and the significant liability associated with a field safety failure. This underscores the demand in regulated sectors like aerospace and medtech, particularly in North America, which is projected to command a 39.5% global share of the engineering consulting market by 2035 according to the latest market report.

A Framework for Selecting the Right Engineering Partner

Selecting the wrong engineering partner introduces significant project and business risk, leading to budget overruns, loss of investor confidence, and market credibility damage. A glossy portfolio reveals little about a firm's ability to execute under pressure. A rigorous evaluation framework is required to differentiate firms that can deliver from those who cannot.

Your evaluation must focus on tangible proof of a structured design process, verifiable industry experience, and disciplined communication protocols.

Key Evaluation Criteria

A top-tier engineering partner will demonstrate how they work, not just what they do. Their processes should be robust enough to manage complexity yet agile enough to adapt. Your vetting should focus on three core areas:

- Process Maturity and Discipline: Do they have a formal, documented development process? Ask for a walkthrough of a typical project, from requirements definition to manufacturing handoff. Look for established procedures for design reviews, version control (e.g., Git), and quality assurance.

- Technical Depth and Verifiable Experience: Move beyond client logos. Request specific examples of projects with similar technical challenges or regulatory constraints. A firm claiming medical device experience should be able to speak fluently about their approach to ISO 13485 and Design History File (DHF) management.

- Communication and Project Management: How will they maintain transparency and alignment? A professional firm will have a clear communication plan, detailing regular status meetings, key contacts, and the tools they use for project tracking (e.g., Jira, Confluence). This is a direct indicator of their commitment to accountability.

Ultimately, selecting the right product development firm is about finding a team whose operational cadence and technical standards align with your own.

Critical Questions to Ask Potential Partners

To accurately assess a firm's capabilities, ask specific, open-ended questions that require substantive answers.

The most telling sign of an experienced engineering firm is not a promise of a problem-free project, but a well-defined process for managing problems when they inevitably occur.

Use this checklist to guide your diligence:

- Scope & Change Management: "Walk me through your process for managing scope changes. Provide a specific example of how you handled a significant change request mid-project."

- Design for Manufacturability (DFM): "At what stage do you conduct DFM reviews, and who from your team is involved? How do you incorporate feedback from contract manufacturers into the design?"

- Risk Mitigation: "Describe your approach to identifying and mitigating technical risk. Do you use formal methods like FMEA? If so, at what point in the project?"

- Problem Resolution: "Describe a project that encountered a major technical roadblock. What was your process for diagnosing the root cause, developing a solution, and validating the fix?"

The responses will reveal far more about their competence and process discipline than any marketing collateral.

From Project Rescue to Market Success: A Real-World Scenario

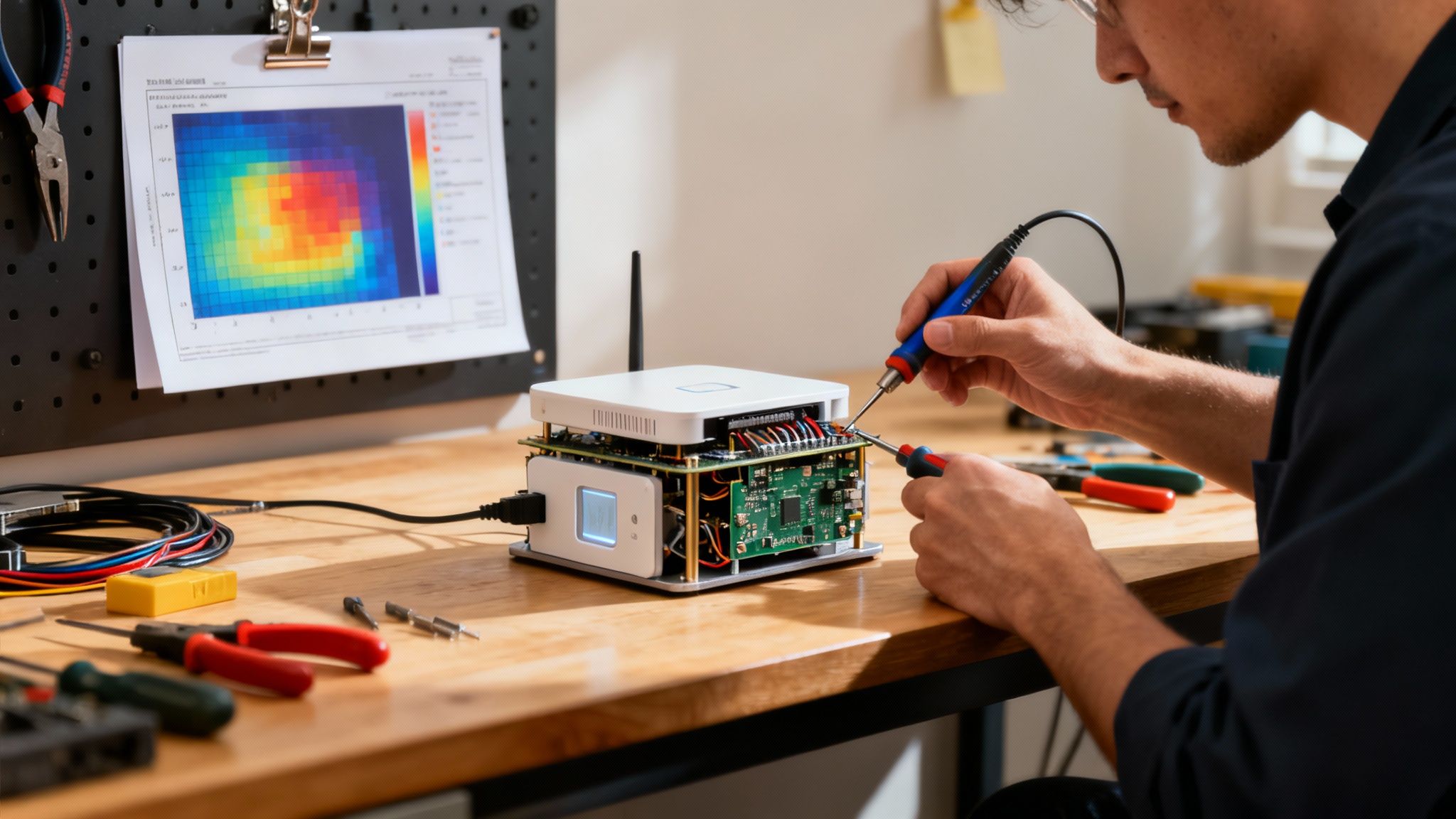

To illustrate how expert engineering design services can recover a failing project, consider a common scenario: an industrial OEM is developing a new IoT sensor, but the project is six months behind schedule with a fixed launch deadline.

Problem → Diagnosis → Solution → Outcome

- Problem: The in-house prototype is non-functional. The firmware crashes intermittently, and the enclosure's poor thermal design causes the main processor to throttle, corrupting sensor data. The project is stalled, burning capital daily and jeopardizing a major product launch.

- Diagnosis: The root cause is a systemic process failure: siloed engineering teams. The hardware and mechanical engineers never collaborated, resulting in a PCB that was thermally incompatible with its enclosure. Furthermore, a formal Design for Manufacturability (DFM) analysis was never performed, meaning the design was unproducible at scale even if it had worked.

- Solution: An integrated team of firmware, hardware, and mechanical specialists was deployed to execute a parallel-path recovery plan.

- Firmware Re-architecture: The firmware was rebuilt on a stable real-time operating system (RTOS) to ensure deterministic performance.

- Hardware Redesign: The PCB was redesigned with improved power planes and a component layout optimized for thermal dissipation.

- Mechanical Engineering: A new enclosure was designed with passive cooling vents, validated with thermal simulations (CFD) prior to tooling.

- Outcome: A robust, fully manufacturable prototype was delivered in six weeks. The client met their launch deadline, averting a significant financial loss and reputational damage. This type of first-pass success is driving growth in the engineering design services market, which is projected to grow from USD 1,141.89 billion in 2025 to USD 1,174.33 billion in 2026, according to The Business Research Company.

Engaging the right engineering design partner is a strategic decision to mitigate risk, accelerate timelines, and control costs. It is about embedding deep, multidisciplinary expertise from day one to ensure a product is not just innovative, but manufacturable, reliable, and commercially successful. A proven B2B strategy for product launch success depends on this solid engineering foundation.

The logical next step is a brief technical assessment to map your project's hurdles and strategic goals. A focused consultation can be the pivotal moment that separates a stalled project from a market-leading product.

Ready to de-risk your project and accelerate your path to market? Schedule a technical consultation with Sheridan Technologies to discuss your specific engineering challenges and objectives.