Firmware is the invisible, high-stakes code that brings hardware to life. For leaders overseeing complex product development, it’s where debilitating risks hide. A single firmware bug can derail a launch, compromise user safety, and trigger costly recalls. This is why engaging embedded firmware development services is not just a tactical delegation; it's a strategic decision to control program risk and ship a reliable product faster.

This guide is for VPs of Engineering, CTOs, and Program Managers responsible for delivering complex electronics under tight schedules and budgets. It's for leaders who understand that late-stage firmware issues can cripple a program. This is not a tutorial for junior engineers. We'll frame the critical decisions required to architect, verify, and ship robust firmware for high-reliability applications, from initial board bring-up through manufacturing ramp.

By the end of this guide, you will be able to:

- Identify the key architectural trade-offs that impact cost, reliability, and time-to-market.

- Structure a firmware development plan that aligns with EVT/DVT/PVT hardware milestones.

- Evaluate a potential partner's capabilities beyond their marketing claims.

Why Firmware Is the High-Stakes Layer in Product Development

If you're a VP of Engineering or a Program Manager, you've felt it: firmware is often the source of the most unpredictable issues on the road from prototype to production. Unlike a mobile app pushed to an app store, a firmware failure in a shipped product is a different class of problem. It can lead to bricked devices, full-scale recalls, and the kind of brand damage that takes years to repair.

This guide is for leaders who must de-risk this critical layer and ensure their hardware performs flawlessly.

The stakes are highest in regulated sectors like medical devices and aerospace, where firmware reliability is non-negotiable and directly tied to safety and regulatory approval. But even in industrial IoT or consumer electronics, unstable firmware erodes customer trust and creates an operational drag on your engineering team.

Navigating the Firmware Challenge

High-performing teams understand that firmware cannot be an afterthought. It demands a disciplined approach woven into the hardware development process from day one. By engaging an experienced partner, you can instill this discipline without the time and expense of building a large, specialized internal team.

A real-world scenario we often encounter is an industrial sensor company moving from a simple wired product to a complex wireless mesh network. Their existing team excelled at analog hardware but lacked deep expertise in RTOS scheduling and low-power BLE stack integration. An early firmware architecture decision to use a non-preemptive scheduler caused intermittent data loss under heavy network load—a bug discovered late in DVT that forced a costly hardware re-spin and delayed their launch by a full quarter. This is precisely the kind of late-stage risk that a structured firmware development process is designed to prevent.

What to Expect From Firmware Development Services

When you partner with a firmware development firm, you are bringing in a specialized team to architect and implement the nervous system of your product. A true partner engages across the entire lifecycle, from initial board bring-up to long-term field support. Their work starts at the most fundamental level with board bring-up—a methodical process of validating power rails, clocks, and boot sequences to create a stable foundation before any application features are built.

From there, the scope expands to writing peripheral drivers, optimizing memory usage, and implementing power management schemes. It’s a constant balancing act between performance and the physical constraints of the hardware.

Core Service Offerings

As you evaluate potential partners, map their core capabilities to your product's specific needs. Most expert firms offer a consistent set of key services:

- Hardware Abstraction Layer (HAL) and Driver Development: This creates a clean interface between your application code and the target MCU. A well-designed HAL is critical for long-term maintainability and simplifies future hardware changes.

- Real-Time Operating System (RTOS) Integration: For devices juggling multiple tasks with precise timing, an RTOS like FreeRTOS or Zephyr is essential. A partner doesn't just install an RTOS; they configure and tune it to guarantee the deterministic, real-time responses your product requires.

- Connectivity Stack Implementation: Integrating wireless protocols like Bluetooth Low Energy (BLE), Wi-Fi, or LoRaWAN is notoriously difficult. Debugging these communication stacks is often one of the most complex parts of an embedded project.

- Bootloader and OTA Update Systems: A secure bootloader is the key to enabling Over-the-Air (OTA) firmware updates. A robust OTA system with rollback protection is essential for fixing bugs and adding features after a product ships.

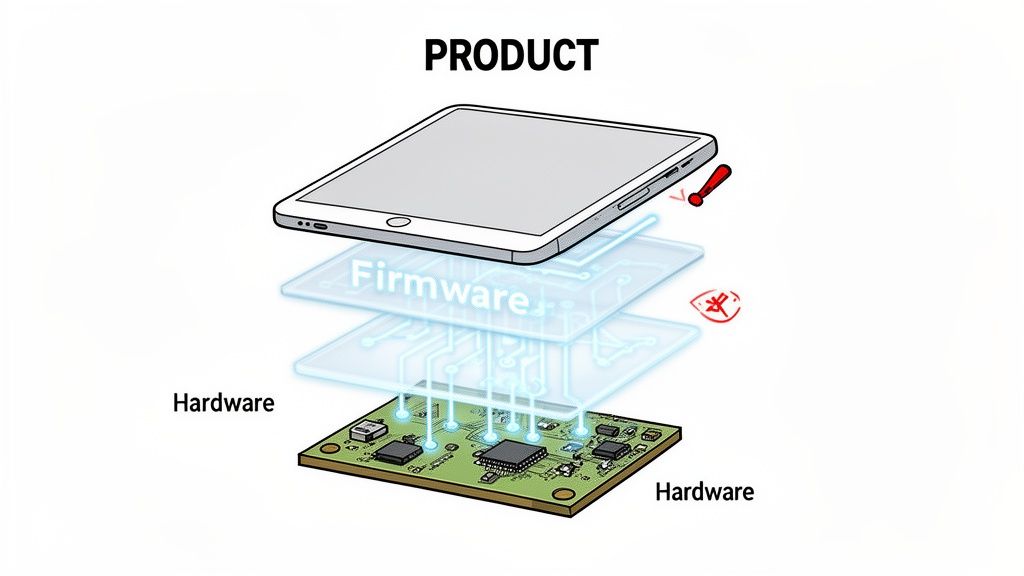

If your hardware is the skeleton, the firmware is the intricate set of instructions from the brain that enables coordinated and reliable action. Without it, the most advanced hardware is just an expensive paperweight.

Common Engagement Models

The right engagement model aligns the partner's team with your project's stage, risk tolerance, and internal resources. Picking the right model helps you draft a precise statement of work, control your budget, and set clear expectations for deliverables.

Firmware Development Engagement Models

| Engagement Model | Best For | Pros | Cons |

|---|---|---|---|

| Project-Based (Fixed Scope) | Well-defined projects with a stable hardware design and clear requirements (typically post-EVT). | Predictable cost and timeline. Clear deliverables defined upfront. | Inflexible to change; scope creep leads to costly change orders. Poor fit for early R&D. |

| Time & Materials (T&M) | Early-stage R&D, board bring-up, or projects with evolving requirements where flexibility is key. | High flexibility to adapt to technical challenges and changing priorities. | Budget is less predictable. Requires strong project management and oversight from the client. |

| Dedicated Team (Retainer) | Long-term, complex programs requiring deep product knowledge and ongoing feature development. | Deep integration with your team. High efficiency and knowledge retention. | Higher cost commitment. Overkill for smaller, well-defined projects. |

| Consulting & Advisory | Architecture reviews, troubleshooting specific issues, or strategic verification planning. | Access to senior expertise on-demand. Cost-effective for targeted problem-solving. | Not intended for hands-on development or full project execution. |

A strong partnership is about navigating the technical minefield of product development. By understanding the full scope of services and selecting the right engagement model, you can effectively de-risk a critical part of your product and ensure your device is reliable, scalable, and ready for manufacturing.

Mapping the Firmware Development Lifecycle

The classic project failure mode—where the last 10% of the work consumes 90% of the budget—often happens when firmware is disconnected from the hardware build process. High-performing teams avoid this by mapping the firmware lifecycle directly onto hardware milestones: Engineering Validation Test (EVT), Design Validation Test (DVT), and Production Validation Test (PVT). This transforms a reactive process into a predictable one.

When firmware and hardware mature in lockstep, you systematically de-risk the entire program. This structured approach is a major reason the embedded firmware services market is growing steadily, with high-reliability sectors demanding disciplined execution.

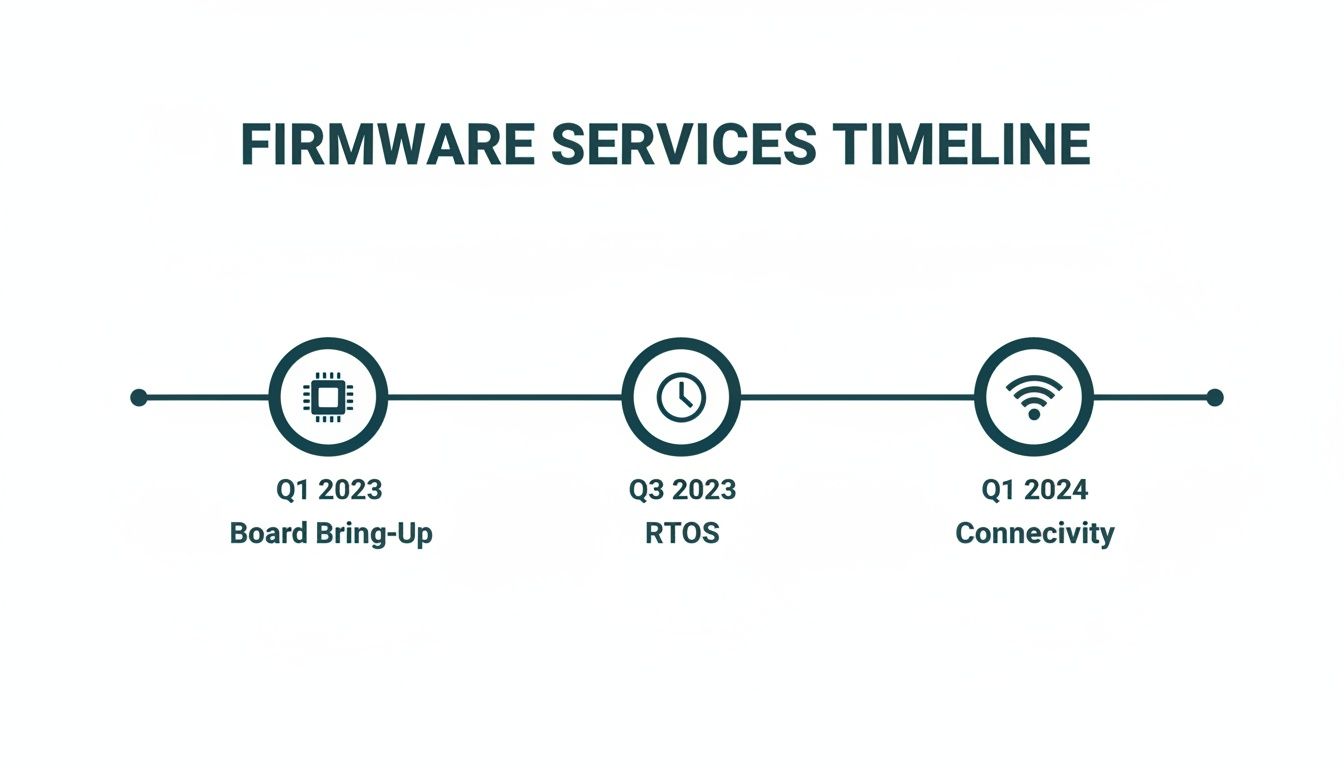

This timeline illustrates how firmware tasks progress alongside the hardware's journey from bare board to mass-produced product.

The work evolves from foundational, low-level tasks to complex application logic, mirroring the hardware's own path to production readiness.

EVT Stage: Focus on Board Bring-Up and Hardware Validation

The EVT phase answers one brutal question: “Does the hardware work?” Firmware’s sole job here is to prove out the electronics. Application features are irrelevant; this is about methodical, low-level validation.

Firmware deliverables for the EVT gate:

- Initial Board Bring-Up: Engineers bring the board to life, testing power rails, validating clock stability, and verifying the boot sequence. You can read our detailed guide on how to test a printed circuit board to understand the depth of this process.

- Hardware Abstraction Layer (HAL) Creation: The foundational HAL is built. This creates a standard way for higher-level software to interface with the MCU's specific hardware, making future code maintenance manageable.

- Basic Driver Implementation: Simple drivers for core buses like UART, I2C, and SPI are written and tested to confirm that the MCU can communicate with all critical chips on the board.

By the end of EVT, the goal is a stable hardware platform with a basic firmware layer that proves every critical component is alive and reachable. Skipping this foundational work guarantees major rework later.

DVT Stage: Building the Application Core and Business Logic

With the hardware confirmed, the DVT phase is where the product truly takes shape. The focus shifts from proving out electronics to building the core functionality. This is where the application logic, real-time behavior, and main features come to life.

Major firmware workstreams in DVT:

- RTOS Integration: A Real-Time Operating System (RTOS) is configured. This involves setting up task schedulers, memory management, and inter-task communication to ensure reliable concurrent operation.

- Application Logic Development: The team writes the code that delivers actual value—whether it’s a sophisticated sensor fusion algorithm or a precise motor control loop.

- Rigorous Integration Testing: As software modules are completed, they are integrated and tested together to find bugs at the interfaces between components and the hardware.

PVT Stage: Hardening for Production and Manufacturability

The PVT stage is the final stretch. The firmware should be feature-complete. The focus shifts entirely to hardening the system for mass production, ensuring it is stable, manufacturable, and ready for long-term field support.

Critical firmware tasks during PVT:

- Manufacturing Test Firmware: A special factory firmware build is created. This includes routines for automated testing, calibration, and securely provisioning each device with unique IDs or keys on the assembly line.

- OTA Update Finalization: The Over-the-Air (OTA) update mechanism is finalized and stress-tested to verify security, reliability, and rollback capabilities.

- Final Stability and Optimization: The last push involves bug hunting, performance optimization, and power consumption tuning to maximize efficiency before shipping.

Making Critical Firmware Architecture Decisions

Firmware engineering is a game of strategic trade-offs. Early architectural choices directly impact cost, reliability, and time-to-market. Getting these foundational decisions right is how high-performing teams avoid late-stage rework and ship products that work reliably. These are business decisions wrapped in engineering language.

Choosing Between Bare-Metal and an RTOS

One of the first forks in the road is whether to build firmware directly on the hardware (bare-metal) or use a Real-Time Operating System (RTOS). This dictates the entire software structure and has massive implications for complexity and scalability.

- Bare-Metal Approach: The code runs in a single, continuous loop. It's a good fit for simple applications with a limited set of sequential tasks, offering minimal overhead and a tiny memory footprint.

- RTOS Approach: An RTOS is essential when a system must juggle multiple tasks with complex timing. It acts as an air traffic controller, scheduling tasks and managing resources to ensure high-priority events are handled immediately. This is non-negotiable for products with hard real-time constraints.

Decision Criteria: Choose bare-metal when the device performs a single, sequential function and BOM cost is the top priority. Opt for an RTOS when the product must handle multiple concurrent tasks, meet strict deadlines, or is expected to grow with new features. An RTOS adds upfront complexity but pays back in predictability and maintainability.

Selecting the Right Microcontroller

The microcontroller (MCU) is the heart of your product. Picking the right one is a critical balance between technical needs, cost, and supply chain risk. An underpowered MCU can't support future growth, while an overpowered one adds unnecessary cost to every unit.

Key factors to weigh:

- Processing Power and Memory: Does the MCU have enough Flash for your code (plus future updates) and enough RAM to handle its most demanding state?

- Peripherals: Does it have the specific communication interfaces (I2C, SPI), timers, and ADCs your design needs?

- Power Consumption: For battery-powered devices, the MCU's sleep-mode current directly translates to battery life.

- Availability and Lead Time: A technically perfect MCU is useless if you can't buy it. Supply chain risk must be a primary consideration.

The market reflects this wide range of needs. In embedded systems, 32-bit processors are common, powering versatile firmware for complex applications. Growth in this market, as detailed in reports on market trends in firmware engineering, is fueled by billions of connected IoT devices demanding secure, real-time firmware.

Architecting for Reliability and Communication

A robust firmware architecture anticipates and contains failures. This means designing reliability patterns directly into the software.

- Watchdog Timers: An independent hardware timer that must be periodically "pet" by the firmware. If the application freezes, the timer is not reset and triggers a system reboot, preventing the device from getting stuck.

- Brownout Detection: This hardware feature monitors the system voltage. If power dips below a safe level, it triggers a safe shutdown or reset, preventing memory corruption.

- Fault Containment: In RTOS-based systems, a fault in one software module must not crash the entire system. Good architecture isolates tasks using memory protection units (MPUs) to enforce boundaries. This is a cornerstone of building secure systems, a topic covered in our guide to improving security in embedded systems.

Integrating robust communication protocols is also paramount. For industrial applications, understanding protocols like the Modbus communication protocol is essential for interoperability. These early architectural choices control cost, mitigate risk, and build products that customers can depend on.

Ensuring Firmware Quality and Regulatory Compliance

In high-stakes industries like medical devices or aerospace, quality isn't just a feature—it's the foundation of the business. A firmware failure in a surgical robot or an aircraft's navigation system has consequences beyond financial loss. This is why a disciplined approach to Verification and Validation (V&V) is non-negotiable.

Cutting corners on V&V is a surefire way to face failed audits, product recalls, and unacceptable safety risks. Experienced teams weave quality assurance into the project from day one to sidestep rework, pass compliance checks, and get to market faster.

Building a Robust Verification and Validation Strategy

A solid V&V plan is a multi-layered defense against defects. It combines different methods to test the firmware at every level.

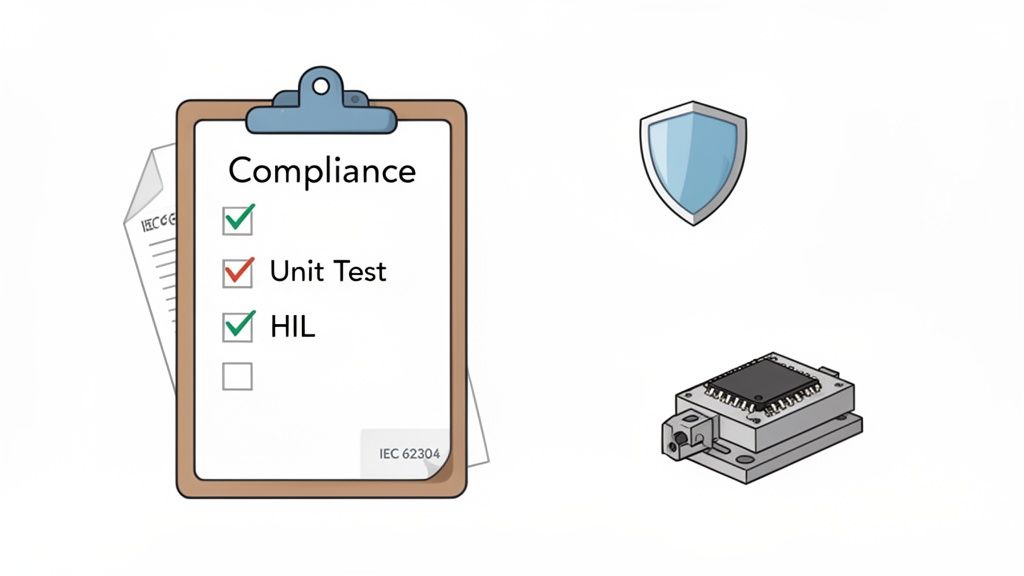

A mature V&V strategy includes:

- Unit Testing: Individual functions are tested in isolation to ensure their internal logic is sound. This catches defects early when they are cheap and easy to fix.

- Integration Testing: Once units are verified, they are combined and tested to check the handoffs between different software modules.

- Hardware-in-the-Loop (HIL) Simulation: The real firmware runs on the target hardware, which is connected to a simulator that mimics its real-world environment. This allows for automated testing of thousands of scenarios that would be dangerous or impossible to replicate physically.

Following automated testing best practices is essential for building dependable and reliable products.

Adhering to Industry-Specific Standards

In regulated industries, you must prove how you built the firmware, following a rigorous, documented process.

For instance, a medical device requires adherence to IEC 62304, the international standard for the medical device software lifecycle. It demands strict process controls, risk management, and complete traceability from requirements through final verification. Similarly, automotive and industrial firmware often must follow MISRA C/C++ coding guidelines, a set of rules designed to eliminate coding errors that could lead to unsafe behavior.

A partner with deep experience in regulated environments doesn't just write code; they generate the evidence of quality required for regulatory filings. This documentation is as critical a deliverable as the firmware itself.

The Business Impact of Compliance Readiness

This focus on quality is a strategic business decision. North America currently leads the global embedded market, a position strengthened by initiatives fueling onshore MCU production for critical sectors like defense and medtech, where trustworthy firmware is paramount for security and compliance.

Teaming up with a firmware partner who has a mature quality management system (QMS) and understands your industry's regulatory landscape is a massive risk-reduction strategy. It ensures your product isn't just functional, but also compliant, safe, and ready to compete.

How to Choose the Right Firmware Development Partner

Selecting an external firmware team is a make-or-break decision. A great partner accelerates your time-to-market while reducing program risk. A poor fit creates technical debt and delays. You're not just looking for coders; you're looking for a partner with a mature, disciplined engineering process.

The key is to look beyond a checklist of technical skills. A capable firm has proven processes that avoid the classic trap of siloed hardware and firmware teams. When those disciplines are disconnected, integration becomes a nightmare. A unified delivery model isn't a "nice-to-have"; it's a non-negotiable trait of any high-performing team.

Key Evaluation Criteria

Your evaluation should stand on three pillars: technical expertise, process maturity, and an integrated development model.

Use this checklist to guide your evaluation:

Technical Expertise and Depth:

- MCU and RTOS Experience: Do they have hands-on experience with the specific microcontroller families and RTOS your product needs? Ask for concrete project examples.

- Domain-Specific Knowledge: Can they speak intelligently about standards relevant to your industry, such as IEC 62304 or DO-178C?

- Test and Verification: A strong partner will bring up unit testing, HIL simulation, and Design for Test (DFT) in the first conversation.

Process Maturity and Discipline:

- Quality Management System (QMS): Do they have a documented QMS? This is a clear sign of a disciplined organization.

- Version Control and CI/CD: How do they manage source code? Are they using continuous integration to maintain code quality?

- Documentation Standards: Ask to see samples like a software architecture document or verification plan. The quality of their documentation reflects the quality of their engineering.

Asking the Right Questions

Generic questions get rehearsed answers. Ask pointed, scenario-based questions that reveal how they operate under pressure.

The most insightful questions are not about what a partner can do, but how they do it. Focus on process, risk management, and the transitions between development stages.

Here are a few questions to cut through the sales pitch:

- "Describe your process for managing the transition from an EVT prototype to DVT production-intent firmware. What are the key gates and deliverables?"

- "Walk me through your verification strategy for a product with a risk profile similar to ours. How do you ensure complete test coverage?"

- "How do you handle hardware-firmware integration issues? Give me an example of a difficult bug you had to track down between disciplines and how you solved it."

Finding the right partner is about aligning their technical expertise and operational discipline with your program’s needs. For a deeper look, explore our guide on what to look for in a full-service product development firm.

A Few Common Questions We Hear About Firmware Services

When technical leaders consider bringing in a firmware partner, a few practical questions always come up regarding cost, timelines, and intellectual property.

What's the Typical Cost Structure for a Firmware Project?

Most projects use either a Time & Materials (T&M) or Fixed-Price model, depending on project maturity.

- Time & Materials (T&M): This is ideal for early R&D and initial board bring-up. When requirements are fluid, T&M provides the flexibility to adapt without constant re-scoping.

- Fixed-Price: Once the hardware design is stable and deliverables are clear, a fixed-price engagement provides cost predictability, which is critical for managing program budgets.

A good partner helps you select the model that best manages your specific program risks.

How Do You Handle Intellectual Property Ownership?

This is non-negotiable. The client must own 100% of the custom intellectual property (IP) created for their project. This should be spelled out clearly in your Master Services Agreement (MSA).

The development partner will retain ownership of their pre-existing tools or libraries (background IP) but grant you a perpetual, royalty-free license to use it as an integrated part of your final product.

What Level of Documentation Should I Expect?

Comprehensive documentation is a core deliverable, not an add-on. It's what makes the firmware maintainable long after the initial project is complete.

At a minimum, you should receive:

- A detailed software architecture document.

- Clean, well-commented source code following a consistent style guide.

- Complete build and configuration instructions.

- A full verification plan with test results traceable to requirements.

For regulated industries, this extends to rigorous traceability documentation that connects every requirement to a specific test case and its result, forming an essential part of the compliance package.

How Long Does Firmware Development Take?

While it depends, we can provide real-world goalposts. A straightforward IoT device might take 3-6 months. A complex medical or industrial control system could easily take over a year.

The timeline is driven by hardware maturity, RTOS requirements, the complexity of algorithms and communication protocols, and the level of verification required for regulatory approvals.

At Sheridan Technologies, we deliver the robust firmware, rock-solid documentation, and clear IP ownership that high-reliability products demand. If you're planning a project and need to de-risk your firmware development, request an architecture consultation with our engineering team.