Bringing a physical product to market is a high-stakes endeavor where early mechanical engineering decisions dictate future success or failure. Underinvesting in upfront engineering rigor—from architecture to manufacturing readiness—directly leads to late-stage rework, expensive tooling changes, and catastrophic field failures. The result is derailed timelines, bloated budgets, and significant business risk.

This guide is for engineering leaders, program managers, and CTOs responsible for navigating the journey from prototype to a reliable, manufacturable product. It is not for those seeking basic CAD services or hobbyist support. We will frame the decision-making process for engaging an expert consulting partner, focusing on the critical disciplines that de-risk a program and align technical execution with business goals.

After reading, you will know how to:

- Define the scope and select a partner for your specific program needs.

- Identify the key deliverables that drive a program toward manufacturing readiness.

- Structure an engagement to reduce risk and maximize value.

What Does a Mechanical Engineering Consultant Actually Do?

Effective mechanical engineering consulting is not just about producing 3D models; it's about bridging the gap between a promising concept and a physical product that works reliably, can be manufactured efficiently, and meets market demands. It is the application of rigorous systems engineering principles to de-risk every stage of the product development lifecycle. A high-performing team turns a brilliant idea into a tangible success by managing technical risk and ensuring manufacturability from day one.

This expertise is increasingly critical. The global market for engineering consulting services was valued at USD 202.8 billion in 2025 and is projected to reach USD 296.2 billion by 2035. Project-based work is expected to command 45.8% of the market by then, reflecting a trend toward leveraging specialized partners for focused product innovation. This approach avoids the fragmented handoffs that introduce risk into complex programs. (Data from Research Nester).

The core services break down into several key disciplines.

Mechanical Architecture and System Design

This foundational phase is where critical upfront decisions are made that dictate the product's success. A seasoned consultant doesn't jump into CAD; they first translate market needs into a robust system architecture that balances performance, cost, and reliability constraints. Miscalculations here are amplified exponentially during development.

Key activities include:

- Material Selection: Choosing materials based on a trade-off analysis of structural integrity, thermal properties, weight, cost, and supply chain availability.

- Mechanism Design: Developing the kinematic systems and moving parts that enable the product's core function, from a simple latch to a complex multi-axis robotic joint.

- Thermal Management: Architecting active or passive cooling solutions (e.g., heat sinks, heat pipes, fans) to prevent critical components from overheating and ensure performance and longevity.

Getting these architectural decisions right is the primary function of high-quality engineering design services, directly impacting final product reliability and per-unit cost.

Simulation and Performance Prediction

Before machining physical parts, simulation tools allow for digital prototyping to predict how a design will behave under real-world stress, heat, and vibration. This is vital for identifying failure modes before they become expensive, time-consuming problems in the lab.

The consultant's value is not just in running software but in interpreting the data to drive actionable design changes. This foresight prevents field failures and significantly reduces the number of physical prototype cycles required.

The two primary simulation methodologies are:

- Finite Element Analysis (FEA): Predicts how a part will react to structural loads, impacts, and vibrations, ensuring it meets durability requirements.

- Computational Fluid Dynamics (CFD): Models fluid (liquid or gas) flow to optimize aerodynamics, enclosure ventilation, or the effectiveness of a heat sink.

Design For Excellence (DFx)

"Design for Excellence" (DFx) is a set of disciplines focused on ensuring a product can be manufactured, assembled, and tested efficiently and at scale. The most critical of these are Design for Manufacturing (DFM) and Design for Assembly (DFMA). High-performing teams integrate these principles from the start, not as a final cleanup step.

A consultant focused on DFM/DFMA will refine a design by:

- Reducing total part count to simplify assembly and lower costs.

- Designing parts for ease of handling and orientation by automation or technicians.

- Selecting manufacturing processes appropriate for the target volume and cost.

- Specifying realistic geometric dimensioning and tolerancing (GD&T) to avoid assembly issues.

This pragmatic focus is what separates a clever concept from a commercially viable product.

Core Mechanical Engineering Consulting Services and Their Business Impact

This table maps each service to its key activities and direct business outcome.

| Service Area | Key Activities | Primary Business Impact |

|---|---|---|

| Mechanical Architecture | Material selection, mechanism design, thermal management, system layout. | Improves product reliability and performance; sets the foundation for unit cost. |

| Simulation & Analysis | Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD). | Reduces physical prototyping cycles and costs; identifies failures before they happen. |

| Design for Excellence (DFx) | Design for Manufacturing (DFM), Design for Assembly (DFMA), part reduction. | Lowers manufacturing costs, simplifies assembly, and improves production speed. |

| Prototyping & Validation | Building functional prototypes, creating test plans, executing verification. | Validates that the design meets all requirements; de-risks the move to production. |

| Manufacturing Handoff | Creating 2D drawings, Bills of Materials (BOM), assembly instructions. | Ensures a smooth, low-risk transfer to the contract manufacturer for mass production. |

Each step is designed to control costs, accelerate timelines, and build quality into the product from its inception.

Prototyping, Verification, and Manufacturing Handoff

The final phase guides the product from digital design to physical reality. A consultant’s role is to manage this critical transition through structured prototyping and verification. This can range from general mechanical design to specialized mechanical engineering services for niche applications like advanced hydraulics.

This stage involves building and rigorously testing prototypes against a formal verification plan to validate that the design meets all system requirements. The process culminates in a comprehensive design transfer package—the final "blueprint" for the contract manufacturer—which ensures a seamless handoff for mass production.

How to Choose the Right Mechanical Engineering Consulting Partner

Selecting a consulting partner is one of the most critical decisions in the product lifecycle. The right partner acts as a force multiplier, accelerating timelines and mitigating risks. The wrong one introduces drag through communication breakdowns, missed deadlines, and a design that is not manufacturable. The goal is to find a partner who functions as an extension of your team, tying technical execution directly to business outcomes. A misstep here can cost months of schedule and hundreds of thousands in rework and tooling changes.

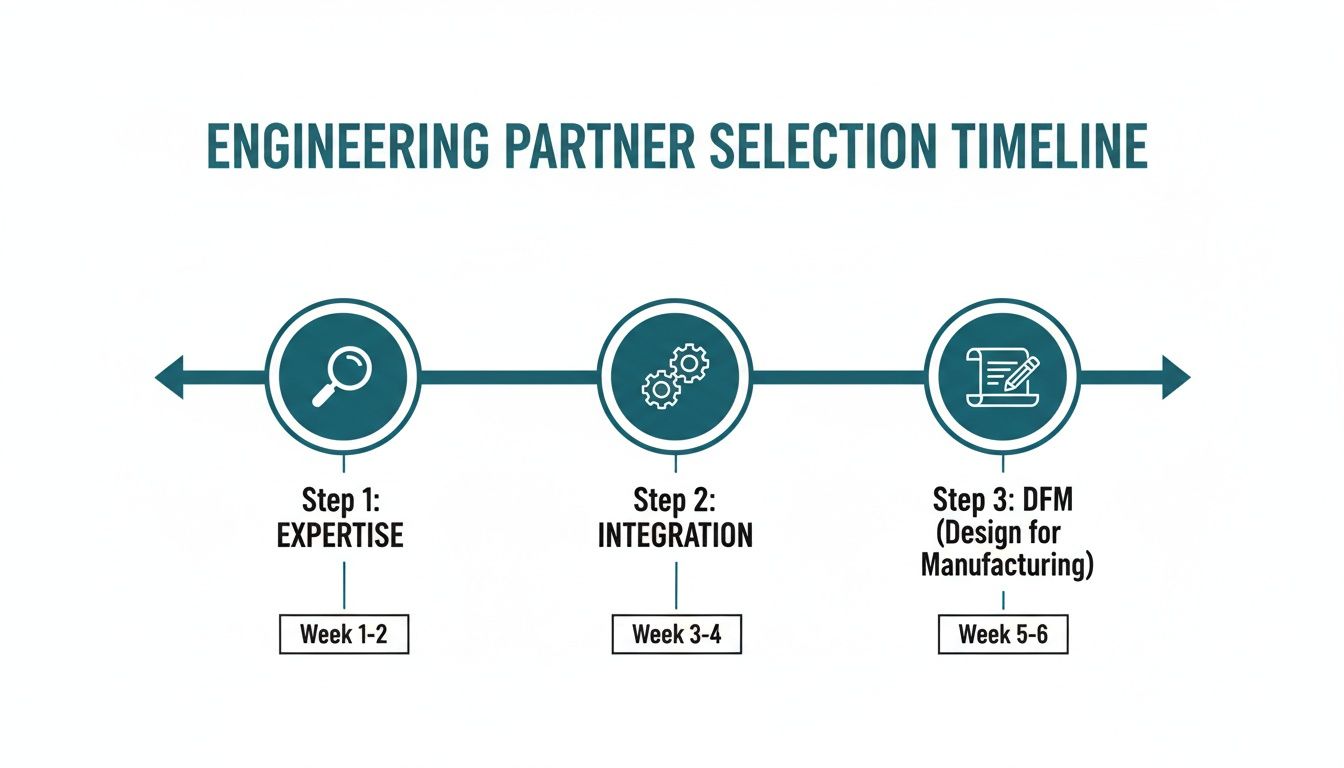

Start with Demonstrable Industry Expertise

Your first filter must be deep, provable expertise in your specific domain. A firm excelling in high-volume consumer electronics may lack the regulatory and reliability discipline required for medical devices or aerospace. Generic design skills are insufficient.

Look for a track record that mirrors your challenges.

- Medical Devices: Do they operate under an ISO 13485-compliant quality management system? Do they have experience with risk management under ISO 14971 and building a defensible Design History File (DHF)?

- Robotics & Automation: Have they delivered complex mechatronic systems? Do they have deep experience in motor selection, gearbox design, and managing thermal loads from high-power actuators?

- Industrial Equipment: Have they designed for harsh environments (shock, vibe, temperature), high duty cycles, and field serviceability?

A partner's value lies in foresight. An experienced firm knows the common failure modes in your industry and designs to avoid them from day one, saving immense time and money.

Context-specific knowledge informs every decision, from material selection to tolerance analysis. A partner who speaks your industry's language can anticipate constraints without a steep, expensive learning curve.

Evaluate Their Integration and DFM Methodology

A brilliant mechanical design is useless if it cannot integrate with the electronics and firmware or be manufactured cost-effectively at scale. You must dig into how a potential partner handles cross-functional collaboration and their commitment to Design for Manufacturing (DFM).

High-performing teams embed DFM as a core principle from the first concept sketch. A partner who treats DFM as an afterthought is a major red flag. They should clearly articulate their methodology for part count reduction, assembly simplification, and designing for specific, scalable manufacturing processes.

Demand for this integrated expertise is growing. The U.S. engineering services market is projected to reach USD 533.33 billion by 2031, with consulting firms employing about 16% of all mechanical engineers. This reflects the value of partners who provide specialized talent for complex tasks like system integration and manufacturing readiness. To learn more, you can discover key insights into the engineering services market.

Ask the Right Questions to Vet Their Process

Once you confirm industry and DFM expertise, probe their operational discipline. Their answers will reveal their maturity and suitability for your program.

Use this checklist of critical questions:

- Risk Management: How do you formally identify, track, and mitigate program risks? (Ask for a sanitized example of an FMEA or a risk burn-down chart).

- Prototype to Production: Walk me through your process for gating a design from EVT to DVT and PVT. What are your specific exit criteria for each stage?

- Supplier Orchestration: How do you engage with contract manufacturers and key component suppliers during the design phase to align on capabilities and costs early?

- Change Management: What is your process for managing Engineering Change Orders (ECOs), particularly after a design freeze?

- Deliverables: What specific documents, files, and drawings are included in your final design transfer package?

A strong partner will provide confident, process-driven answers. They will show measurable artifacts and demonstrate a systematic approach to eliminating late-stage surprises—the hallmark of a firm that delivers robust, manufacturable products on schedule and on budget.

Navigating the Project Lifecycle from Concept to Production

Bringing complex hardware to market is a structured journey, not a chaotic scramble. The best mechanical engineering consulting engagements follow a phased process designed to systematically reduce risk at every stage. This roadmap guides a product from concept to a production-ready reality, using the discipline needed to avoid late-stage surprises that destroy budgets and timelines.

The process begins with a rigorous Discovery and Architecture phase. Here, market needs are translated into a System Requirements Document (SRD). Potential risks are identified and mapped, and core architectural decisions are locked in. Achieving this alignment upfront is what separates successful projects from those doomed to endless rework.

This infographic outlines the key phases for engaging a consulting partner.

Success hinges on early alignment around technical expertise, system integration, and a clear plan for manufacturability—long before detailed design begins.

From Prototype Builds to Production Gates

With the architecture defined, the project advances through a series of orchestrated prototype builds: EVT, DVT, and PVT. Each stage has a distinct purpose and serves as a critical quality gate.

- Engineering Validation Test (EVT): The first integration of all subsystems. The goal is to prove the core design functions as intended and meets key performance specifications. EVT units are often hand-built to validate architectural decisions and identify major integration issues.

- Design Validation Test (DVT): At this stage, the design is "frozen." DVT units are built using production-intent tooling and processes. They undergo exhaustive testing (environmental, stress, drop, regulatory pre-screening) to prove the product is robust and reliable.

- Production Validation Test (PVT): The final gate before mass production. PVT is a trial run on the actual manufacturing line to validate the assembly process, test fixtures, and quality control procedures at scale.

A gate is not passed until its predefined exit criteria are met. This disciplined approach prevents unresolved issues from carrying forward and is essential for shipping complex hardware with confidence.

A Real-World Scenario: Ruggedized Medical Device

Consider a handheld diagnostic device for first responders. Failure is not an option. A mechanical engineering consultant must address several unique challenges from the outset.

The core challenge is balancing extreme durability with the stringent requirements of a medical product. It must survive drops onto concrete and resist water ingress while managing thermal loads and being usable with gloved hands.

Here's how the lifecycle would break down:

- Discovery: The non-negotiable requirements are defined: IP67 water/dust resistance, survivability from a 1.5-meter drop, and strict thermal limits to protect both the user and internal electronics. These are captured in the SRD.

- EVT: The initial enclosure design, sealing strategy (gaskets, overmolding), and thermal solution (e.g., internal heat spreader) are prototyped and tested. Early drop and ingress tests immediately reveal design weaknesses.

- DVT: The refined design, using production-intent materials, undergoes formal verification. This includes HALT/HASS testing, repeated drop tests from all orientations, and water ingress testing to certify the IP rating.

- PVT: The manufacturing line is validated to ensure every unit's seal is installed and tested correctly, often using automated pressure decay tests to confirm integrity.

Demand for this level of robust design is growing. The top MEP Giants—leading firms in mechanical, electrical, and plumbing engineering—posted $15.02 billion in design revenue in 2025, a 2.6% increase. This growth highlights the need for expert mechanical consulting where hardware must integrate flawlessly with complex systems—a core strength Sheridan Technologies provides to our defense and medical clients. You can read more about these engineering design revenue trends.

The Final Handoff: Manufacturing Readiness

The project culminates in the handoff to production. This is more than emailing CAD files; a world-class partner delivers a comprehensive design transfer package. For managing complex designs, our guide on leveraging configurations in SOLIDWORKS offers practical strategies for organization.

This package becomes the manufacturer's single source of truth and must include:

- Finalized 3D CAD and 2D drawings with full GD&T.

- A locked Bill of Materials (BOM) with qualified vendors.

- A comprehensive manufacturing test plan and fixture specifications.

- Detailed assembly instructions and quality control criteria.

In regulated industries like medical devices, this package is a cornerstone of the Design History File (DHF), providing objective evidence that the product was designed and validated under a controlled process. A thorough handoff is the final step in de-risking the transition to mass production.

Common Failure Modes and How to Mitigate Them

Even well-planned projects encounter turbulence. The difference between a minor course correction and a program failure is often the ability to identify risks before they materialize. High-performing engineering teams don't just fight fires; they anticipate where they will start. Several classic pitfalls consistently derail unprepared hardware programs. Ignoring them is a direct path to budget overruns, missed deadlines, and product failures.

The Assembly Line Catastrophe: Poor Tolerance Analysis

One of the most frequent and costly mistakes is inadequate tolerance analysis. A design can appear perfect in CAD, but without a rigorous stack-up analysis of how individual part tolerances accumulate, you are ensuring an assembly line disaster. When production parts arrive and fail to fit together, chaos ensues. This problem typically surfaces during DVT or PVT builds with the first production-intent parts.

Early Warning Signals:

- "Magic" Prototypes: Early hand-built prototypes work, but performance varies significantly between units. This indicates technicians are making undocumented tweaks to force parts to fit.

- High Scrap Rate: During initial builds, a surprising number of parts or sub-assemblies are discarded because they do not mate correctly.

- Late-Stage ECOs: The design was supposedly "frozen," but a flood of Engineering Change Orders (ECOs) is required to adjust part dimensions for fit.

The only prevention is to make formal tolerance analysis (e.g., worst-case, Root Sum Squared) a non-negotiable step for all critical interfaces. It is a core discipline of robust mechanical design.

The Silent Killer: Inadequate Thermal Design

Another classic failure mode is improper thermal management. Modern electronics pack immense power into small spaces, generating significant heat. Without a deliberate thermal strategy, components overheat, leading to performance throttling, premature failure, and safety hazards. This problem often remains hidden until a device is operating at full load in a real-world environment—a dangerous time to discover a fundamental design flaw.

An effective thermal solution is designed in, not bolted on. Discovering an overheating issue at DVT is a recipe for a major redesign that can impact the enclosure, PCB layout, and the entire product schedule.

Mitigation must begin in the architectural phase. Use early CFD simulations to model airflow and heat dissipation. Select critical components with thermal performance in mind and design an integrated solution from the start, whether it's a custom heat sink, heat pipes, or intelligent ventilation.

The Profit Drain: Overlooking DFM Principles

The third major trap is designing a product that is difficult or expensive to build. Overlooking Design for Manufacturing (DFM) principles can render a product commercially non-viable. This includes overly complex part geometries, unnecessarily tight tolerances, or manual assembly steps prone to human error.

For a deeper dive, read our guide on the principles of Design for Manufacture and Assembly.

The most effective mitigation is to involve your contract manufacturer—or a consulting partner with deep manufacturing experience—early in the design cycle. Their feedback on manufacturability can prevent costly tooling rework and high unit costs. A formal process FMEA (Failure Mode and Effects Analysis) is another powerful tool, forcing the team to systematically consider what could go wrong in manufacturing before production begins.

Mechanical Development Risk Mitigation Checklist

This checklist helps teams identify common risks early, before they impact schedule and budget.

| Risk Area | Early Warning Signal | Mitigation Strategy |

|---|---|---|

| Tolerance Stack-Up | Inconsistent prototype performance; high scrap rate in early builds. | Mandate formal tolerance analysis (Worst-Case, RSS) on all critical interfaces. |

| Thermal Management | Components running hot in early tests; no thermal simulation data. | Conduct early CFD analysis; select components with thermal limits in mind. |

| Manufacturability (DFM) | Complex part geometries; overly tight, unjustified tolerances. | Engage contract manufacturer for DFM reviews early and often; conduct a formal FMEA. |

| Material Selection | Materials chosen based on CAD properties alone, without physical testing. | Build and test "looks-like, works-like" prototypes with production-intent materials. |

| Structural Integrity | Parts failing during drop tests or vibration analysis late in the project. | Use FEA simulations early in the design phase to identify and reinforce weak points. |

| Supplier Risk | Key components are single-sourced from a new or unvetted supplier. | Qualify a second source for all critical components before design freeze. |

By monitoring for these warning signs and implementing these strategies, you can significantly de-risk your project and build a more robust, manufacturable, and profitable product.

Putting Your Mechanical Engineering Strategy Into Action

Understanding the mechanical engineering lifecycle and its potential failure modes is the first step. Now, it's time to take deliberate action to get ahead of these risks. The most powerful change is not tactical but cultural: treat mechanical engineering as a strategic pillar of product development from day one.

Conduct a Gap Analysis of Your Current Program

Begin with an honest internal assessment. Use the lifecycle stages discussed in this guide as a mirror for your current project. This requires brutal honesty about your team's capabilities and processes.

- Design for Manufacturing (DFM): Is DFM integrated into your process from the initial concept, or is it a last-minute activity before quoting?

- Verification Planning: Do you have a formal verification and validation (V&V) plan that traces every requirement to a specific, repeatable test method?

- Supplier Readiness: Is your contract manufacturer engaged early in the design process, or is the plan to "throw the design over the wall"?

This gap analysis will illuminate your biggest risk areas and provide a data-driven starting point for an action plan.

Implement High-Impact Process Fixes

Once you identify the gaps, you can implement focused improvements. You don't need to re-engineer your entire organization. Small, targeted changes can dramatically alter a project's trajectory.

A powerful next step is to schedule an internal design review focused exclusively on manufacturability and testability. Bring engineering, operations, and quality into the same room to analyze the design from these two perspectives. This cross-functional review consistently uncovers critical issues that siloed teams miss.

The goal is to create a scorecard. Benchmark your existing partners or build a framework for evaluating new ones based on the criteria outlined here. This moves your selection process from subjective preference to objective, data-backed decision-making.

For teams facing stalls or needing to accelerate a timeline without taking on unmanaged risk, engaging an expert partner for a targeted assessment is a logical next step. An experienced external perspective can diagnose the root cause of a problem and define a clear, actionable path forward.

Common Questions from the Trenches

Engineering leaders often have the same core questions when considering a mechanical engineering consulting partner. Here are the most common ones we hear.

When Is the Right Time to Hire a Mechanical Engineering Consultant?

The best time to engage an expert is during the initial concept and architecture phase. Involving a consultant early allows them to influence foundational decisions that impact cost, manufacturability, and reliability. This acts as preventative medicine for your program, using early expert guidance on technology selection, material choice, and DFM strategy to prevent costly rework later. That said, a strong firm can add significant value at any stage, whether rescuing a stalled project, optimizing an existing design for cost, or preparing a product for the transition to high-volume manufacturing.

What Is the Difference Between a Freelance ME and a Consulting Firm?

This is a critical distinction. A freelance mechanical engineer is a valuable resource for specific, well-defined tasks, like executing CAD modeling or a straightforward analysis. It is a targeted resource for a narrow scope.

A consulting firm like Sheridan Technologies is a strategic partner engaged to de-risk an entire program. You are not just hiring an engineer; you are gaining access to a structured development process, a multi-disciplinary team, dedicated program management, and clear accountability for the outcome. Firms bring established quality systems, deep experience with regulatory compliance, and the ability to scale resources to meet project demands. This reduces your management overhead and allows you to focus on strategic goals.

What Are the Typical Deliverables I Should Expect?

Deliverables are the tangible artifacts of engineering rigor and should be tied directly to project milestones and gates. Vague promises are a red flag.

You need a clear paper trail of progress. Key deliverables should include a System Requirements Document (SRD), detailed 3D CAD models and 2D drawings with proper GD&T, a comprehensive Bill of Materials (BOM), and all relevant simulation reports (FEA, CFD). The engagement should culminate in a bulletproof design transfer package for your manufacturer, containing every file, assembly instruction, and manufacturing test plan they'll need to succeed.

Ensure every deliverable is clearly defined in the Statement of Work before the engagement begins.

How Are Mechanical Engineering Consulting Projects Typically Priced?

Pricing models vary based on project needs. The three common structures are:

- Time & Materials (T&M): Best for projects with an uncertain scope or early-stage R&D. You pay an hourly rate for work performed, providing maximum flexibility when the path forward is not fully defined.

- Fixed-Price: Ideal for well-defined projects with clear deliverables. This model offers budget certainty from the outset, making it suitable when scope is locked.

- Retainer: A fixed monthly fee provides ongoing, on-demand access to engineering support and strategic guidance. This model is a good fit for companies needing consistent expert oversight without a full-time hire.

The best model depends on your project's maturity and the clarity of its requirements. Regardless of the model, insist on a detailed Statement of Work that explicitly defines the scope to avoid surprises.

At Sheridan Technologies, we provide the strategic guidance and rigorous execution needed to move complex products from concept to production with confidence. If you're facing a mechanical design challenge or need to de-risk your next hardware program, let's talk.